One of the very first SCUBA unit developed in Italy starting from original ideas and technical solutions that did not somehow follow the scheme of the Cousteau-Gagnan CG-45 breathing apparatus, was the "Tricheco" model (Walrus in English) patented by Roberto Galeazzi Junior and produced and distributed by Pirelli, a company much better known today as a tire manufacturer.

Before moving into the technical analysis of this particular self-contained breathing apparatus, which is probably one of the rarest and most unknown models for the scuba diving equipment history lovers, it is worth briefly recalling the history of the inventor of this device, Roberto Galeazzi Junior. Born in Turin in 1911, he was the son of Roberto Galeazzi Senior, born in Livorno in 1882 and founder of the famous company “Roberto Galeazzi” based in La Spezia.

The company, founded in 1930 in La Spezia and finally merged into DRASS in the 1980s based in Livorno, had its moment of maximum notoriety in the early 1930s thanks to the recovery accomplished by the divers of the ship "Artiglio", of the treasure from the ship “Egypt”, which sank in the English Channel with its cargo of gold and silver ingots. Thanks to this undertaking, the name Galeazzi took on a worldwide resonance as the special butoscopic turret, designed by Alberto Gianni, chief diver of the Artiglio, to coordinate the recovery operations with direct observation at the same depth as the wreck, was engineered and built by Roberto Galeazzi Senior.

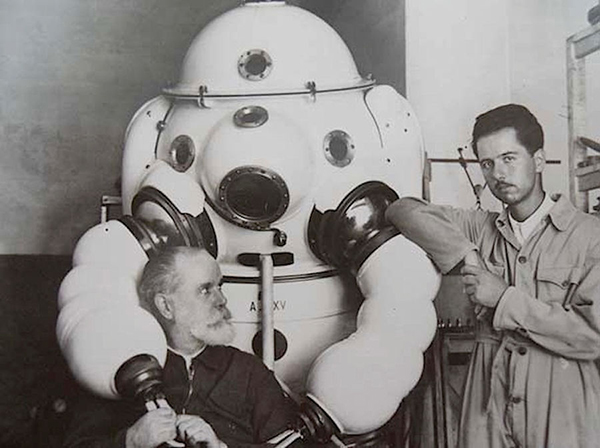

In almost half a century of activity, the Galeazzi company designed and built an impressive number of equipment mainly intended for underwater work including articulated diving suits for great depths, hyperbaric chambers but also helmets and complete diving equipment. The company was, for several decades, also one of the main suppliers of the Italian Navy but also exported its products to many parts of the world. Galeazzi father and son (see Figure 1 which shows both of them in front of one of their articulated diving suits for great depths) were above all great inventors and engineers with several dozen of patents filed in the main countries of the world.

fig. 1

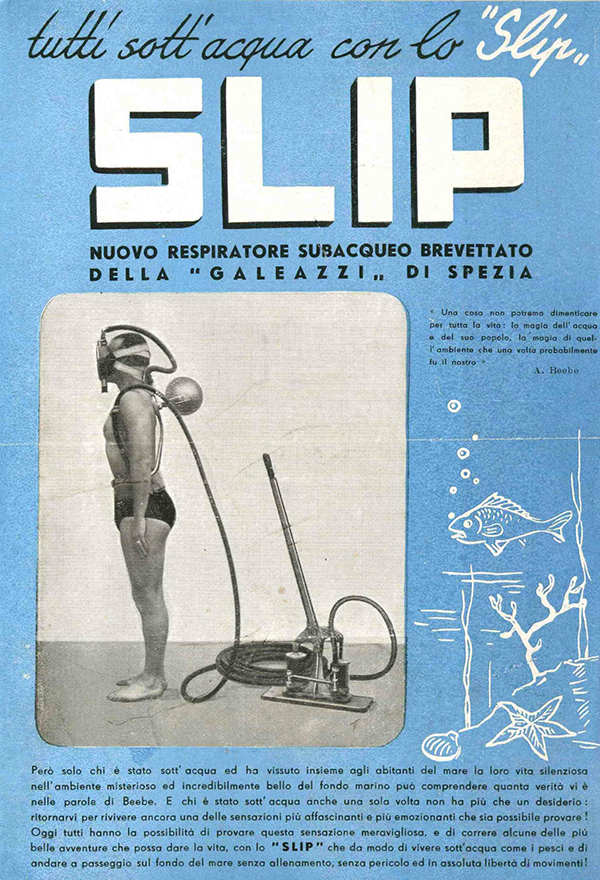

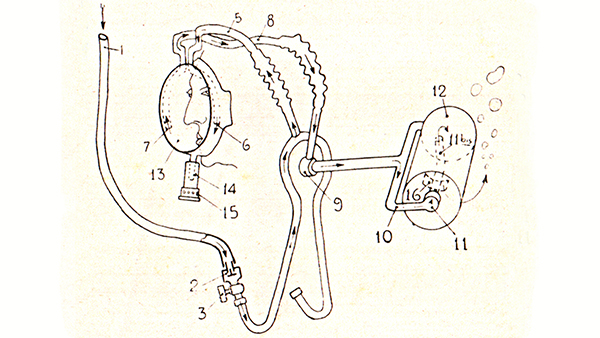

Although the Galeazzi company was mainly interested in the commercial diving market, Roberto Galeazzi Junior was always attracted by the business perspectives coming from the arising sport and recreational diving market even if this, between the end of the 40's and the beginning of the years '50, was still taking its first steps in Italy. The first attempt in this direction was made with the “SLIP” a shallow-depth breathing system fed from the surface by a manual pump. The "heart" of the system, which was in any case covered by a patent both in Italy and in the USA, was the special air tank open at its base and equipped with a gimbal with two axes perpendicular to each other (see Figure 2 and Figure 3).

fig. 2 |

fig. 3 |

This device, patented by Galeazzi in 1949, allowed storing a quantity of air available for the diver's breathing and at the same ambient pressure, regardless of the longitudinal and lateral inclination of the diver's body. The device, which was used among others by the journalist, explorer and writer Lino Pellegrini during his dives in the Canary Islands (see Figure 4 and Figure 5), a totally virgin environment at that time and described in his famous book "Sub, The Book of the Abyss" of 1957, did not have a great commercial success above all because it required the continuous assistance on the surface of an operator willing to shoulder the burden of pumping during the entire duration of the dive, a requirement not compatible with a sporting and recreational use.

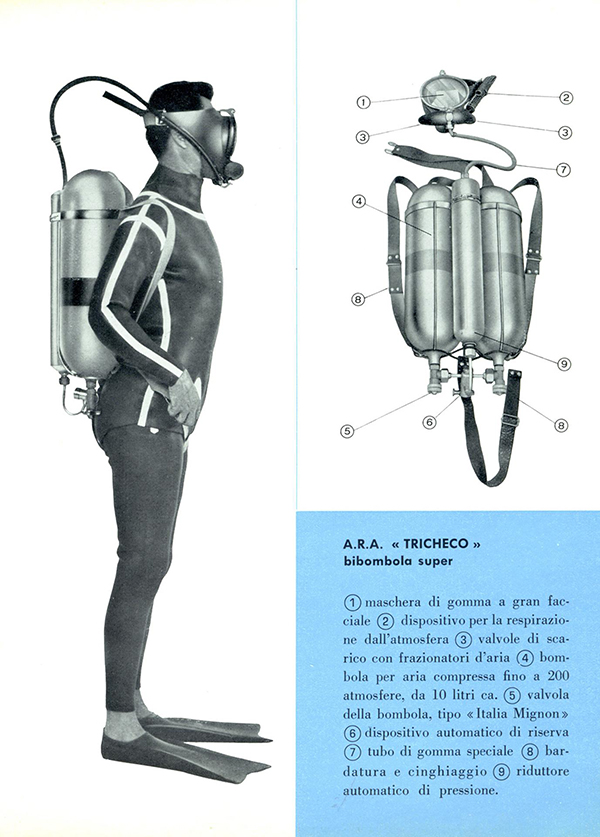

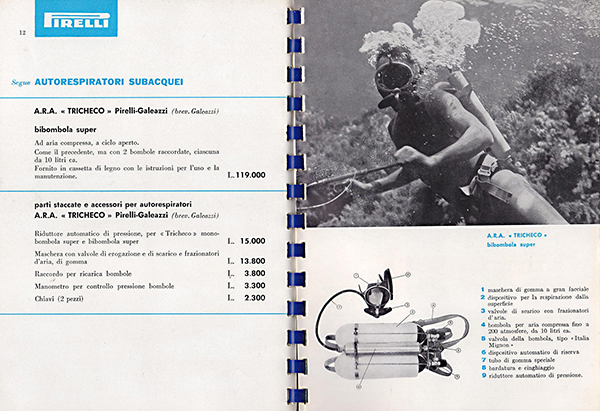

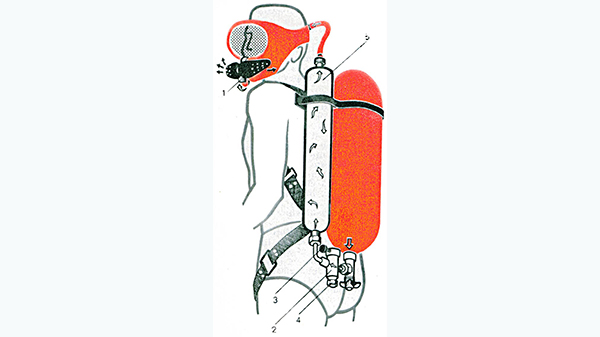

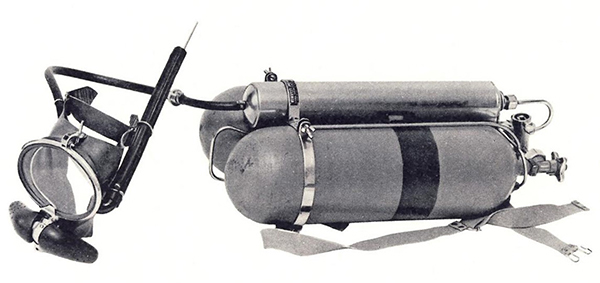

Another Galeazzi's attempt of approaching the sports market was made with the "Tricheco" model, a project that saw the light in 1955, the same year in which the Mistral by La Spirotechnique was born, a model that would have defeated most of the competition in subsequent years. However, in order to have wider commercial opportunities, compared to those that his own distribution only could guarantee, Galeazzi entered into an agreement with Pirelli of Milan, a company that at the time had its own well developed line of manufacturing, production and sale of goods for water sports (air inflatable boats and mattresses, masks, fins, wet and dry suits, oxygen rebreathers, spear guns, diving accessories, etc.). This line of products was concentrated in the Seregno facility near Milan. In those years Pirelli was one of the very few Italian companies active in that specific water sports market together with Cressi of Genoa and Salvas of Rome. This self-contained air breathing apparatus was then included in the Pirelli catalog (see Figure 6 and Figure 7) together with the oxygen rebreathers and, starting from 1960, also with the other famous Pirelli Scuba unit provided with partial gas recirculation system, the Explorer.

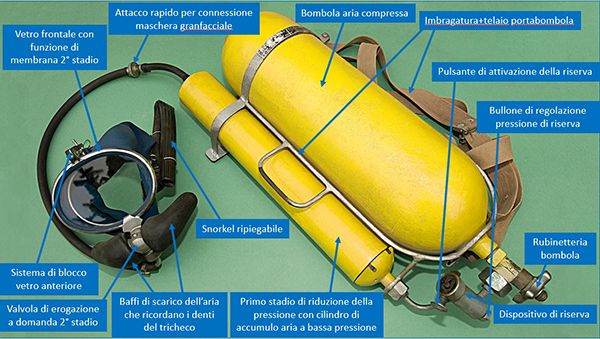

This scuba unit could be sold with one or two air tanks and with or without the special automatic reserve device. This device was equipped with a reserve pressure adjustment bolt and with a reserve activation button. The first stage pressure reducer was integrated in the small diameter cylinder installed on the side of the main air tanks.

fig. 4 |

fig. 5 |

fig. 6 |

fig. 7 |

The "Tricheco" (see Figure 8) was based on a pressure reducing first stage of pressure capable of generating a very low intermediate pressure (about 1-2 bar higher than the ambient pressure as stated in the description of the US patent) and on a full-face mask that included a second stage demand valve which was installed on the lower end of the mask. The specific features of this mask consisted of the front glass, which also acted as the driving diaphragm for the second stage demand valve (a similar solution used years later in the Scubapro "Visionaire" mask designed by the US citizen Charles Hubbel Hawley) and the typical rubber hoods specifically designed for exhausting the exhaled air. These hoods were installed one on each side of the demand valve and resembled walrus teeth (and this is the reason for the characteristic name chosen for this equipment).

fig. 8

According to the designer's intentions, the small holes made on most of the surfaces of these rubber hoods were supposed to reduce the size of the exhaust air bubbles and the associated noise. As for the solution of the front glass that acted as a diaphragm for the second stage demand valve, this solution was not entirely original by itself, since it had also been used in the past for pending patents, however Galeazzi claimed the special connection and rotation of the rubber body of the mask which, in his opinion, made the solution much more effective in terms of performance of the demand valve.

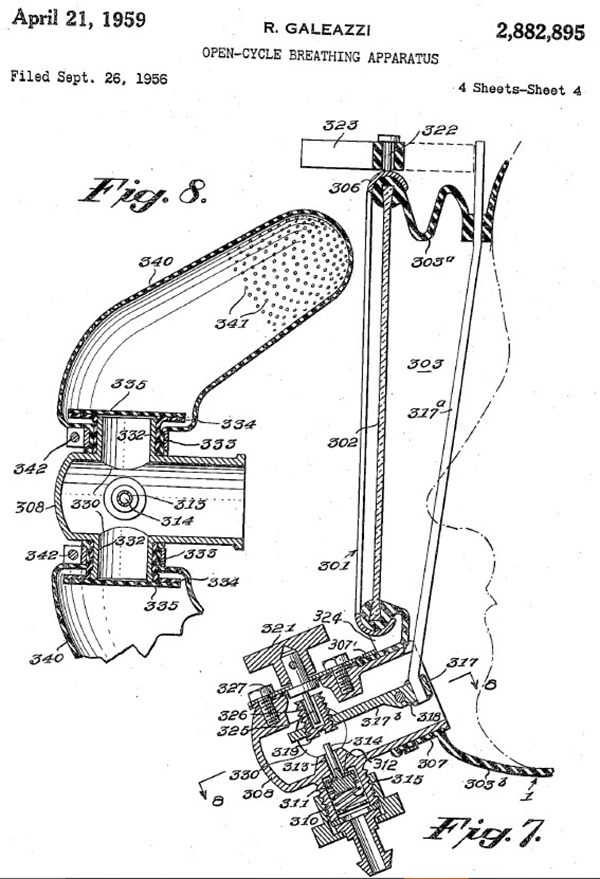

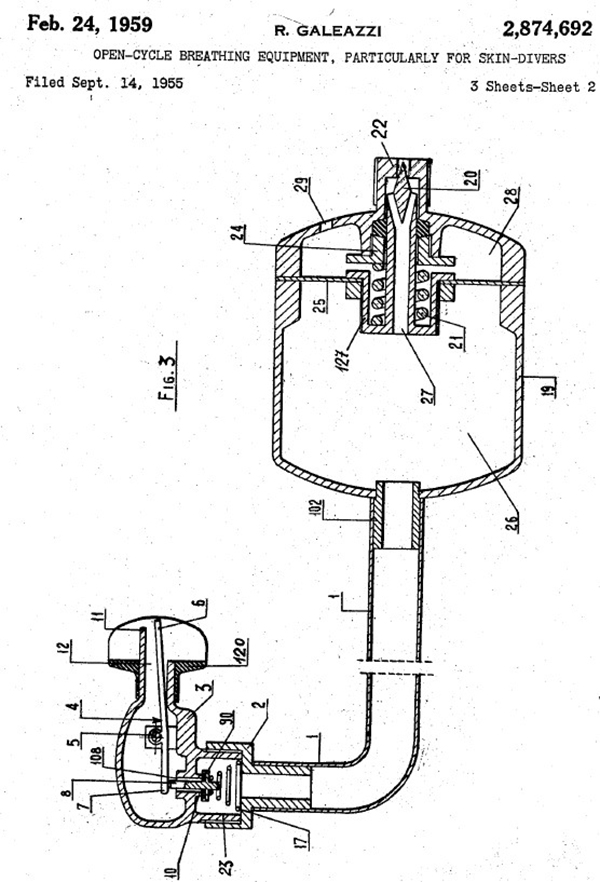

Despite the fact that the main components of this device have also been patented in the USA with patent applications filed starting from 1955 (see the related photos in this article), I have not found any trace of any Tricheco sold or distributed in North America (a different fate compared to his brother Explorer which was actually distributed in those years in the USA, unfortunately without great success). The mechanical operation of this device can be easily deduced by observing Fig.7 and Fig.8, contained in the US2,882,895 patent (filed on 25 September 1956 and granted on 21 April 1959) and Fig.3, contained in the US2,874,692 patent (filed September 14, 1955 and granted on February 24, 1959) (see Figure 9 and Figure 10).

The glass of the full face mask is mounted on a kind of rubber bellows which is an integral part of the rubber body of the mask. The bellows is much more flexible at the top than at the bottom of the mask. Inhalation by the diver thus causes a rotational movement not only of the glass but also of its frame and of the external body of the air supply demand valve. The mask is also equipped with a mechanical element which is fixed during the breathing phases. This element consists of a semi-circular stainless steel frame connected at the top to the rubber body of the mask in an area very close to the diver's forehead and therefore virtually insensitive to the movements of the bellows. In the lower area, the same frame ends with a metal element arranged axially to the external body of the demand valve. This element is also fixed and insensitive to the rotary movements of the external body of the mask. The rotation of the external body of the valve during the inhalation phase brings the stem of the "upstream" type delivery valve in contact with the central fixed element, thus triggering air flow. During the exhalation phase, rotation reverses and the delivery valve closes.

fig. 9 |

fig. 10 |

At the same time, the exhaled air is discharged through the two one-way side valves shown in patent Fig. 8 and subsequently through the small holes made on the surfaces of the rubber hoods. Another curiosity relating to the use of this device and visible from the details of patent Fig. 7 is the following: when the diver is swimming on the surface and is breathing through the snorkel in its fully extended configuration, it was necessary to engage a special mechanical block (item 323) in the upper part of the mask to prevent the front glass of the mask from moving during the inhalation phase and then producing a not necessary air flow from the second stage demand valve.

The operation of the first stage pressure reducing valve is illustrated in the aforementioned Fig.3. This is a downstream diaphragm type pressure reducing valve with an unbalanced pressure conical sealing element. Given the very low downstream pressure (1-2 bar above ambient pressure) and the effect of pressure drop along the hose carrying the air flow to the second stage delivery valve, the designer had to include, downstream of the first stage reducing valve, an air accumulation tank (the characteristic cylinder coaxial to the air tanks of the scuba unit) to prevent interruptions in the air flow during the inhalation phase.

The most difficult part in writing this article was to find some examples of this scuba apparatus to photograph, thus enriching the very scarce photographic documentation available and being able to provide even those construction details that were not otherwise visible. In fact, apart from the Pirelli catalogues, the only photos available of a physical specimen of this unit were those taken in 2009 in Florence by my journalist and collector friend Luigi Fabbri who had the opportunity to view and photograph the vast collection of diving equipment owned by Giuliano Miniati, one of the Tuscan pioneers of diving who worked in Florence and its surroundings since the end of the 50s. It is not a coincidence that some of the photos used in this article and kindly provided by Luigi refer precisely to the specimen from the Miniati’s collection. Luigi had already talked about this very rare model in some of his past articles that appeared in magazines dedicated to the history of diving; he had also cataloged it in his famous website dedicated to the history of Scuba diving www.blutimescubahistory.com.

Apart from this specimen, in many years of research I had not identified other Tricheco owners both in Italy and in the rest of the world. Then suddenly, a few months ago, the situation changed dramatically. In the meantime, by a real stroke of luck, I got in touch with a Portuguese collector who, for personal reasons, had decided to sell his entire collection of double-hose scuba regulators. Among the photos I was checking to identify the pieces to buy for my collection, there were some that immediately caught my attention (see Figure 11 and Figure 12).

fig. 11 |

fig. 12 |

At last, I too had found a Tricheco! Unfortunately, this unit was not complete as there were no air tanks and harness, but everything else was there even if in apparently miserable conditions. Fortunately, after receiving it, I noticed that the full face mask, which apparently looked in very poor conditions, was instead well preserved with the rubber parts largely intact and therefore could be restored to a good shape after some deep cleaning and rebuilt efforts. The most complicated part of the rebuilt was the reconstruction of the special foldable snorkel that was missing in the sample I had purchased. This element has been rebuilt based on the few available photos of Tricheco full face masks still provided with the original component. After this cleaning and rebuilding work my Tricheco was brought back to acceptable condition and included in my display of vintage diving equipment (see Figure 13, Figure 14, Figure 15 and Figure 16).

fig. 13 |

fig. 14 |

fig. 15 |

fig. 16 |

Following this restoration, I published a post on one of the social groups dedicated to vintage diving and, among those who posted comments, I also discovered two collectors who owned complete Tricheco units. The first of these, Cesare Valle from Rome, has a yellow single tank unit with a slightly deteriorated full-face mask but still equipped with the original foldable snorkel (see Figure 17 and Figure 18).

fig. 17 |

fig. 18 |

The second of them, Angelo Silvestri from Latina, has a light blue double tanks unit in almost perfect condition and still equipped with the original wooden box that was used to stow and transport this device (see Figure 19 and Figure 20).

I sincerely thank these two collectors for their availability and kindness in providing me with all the photos and information in their possession that allowed me to write this article. Thanks also to their important contribution, it will be possible to pass on to new generations of diving gear history lovers the knowledge of this scuba model, thus saving it from the oblivion in which it now seemed inevitably destined.

fig. 19 |

fig. 20 |

I sincerely thank these two collectors for their availability and kindness in providing me with all the photos and information in their possession that allowed me to write this article. Thanks also to their important contribution, it will be possible to pass on to new generations of diving gear history lovers the knowledge of this scuba model, thus saving it from the oblivion in which it now seemed inevitably destined.

The photos of the two collector friends made it possible to clarify some important design and construction aspects of this device. Starting with the compressed air tanks, observing the data marked on the top of these (see Figure 21 and Figure 22), we could get the following information:

- The manufacturer of these tanks was Dalmine, probably the most important Italian steel company of the time. These tanks were the first ever to be designed and built specifically for scuba diving and with a volume suited to the diving time requirements that the new scuba units needed. In fact, until the mid-1950s, the only gas tanks available in Italy and capable of working at sufficient pressures were those used in the oxygen breathing systems of military aircraft. The problem with these tanks was the volume which was around 2 liters, a volume suitable for closed circuit oxygen rebreathers (A.R.O.) but not for air scuba units.

- The other important information marked on the top of these tanks is the working pressure which is 200 kg / cmq, a very high value for those times when most of the cylinders available could work at significantly lower pressures (normally 150 kg / cmq).

- The internal volume was 12.7 liters, a different measure than today's standards and the weight was 13.5 kg completely in line with that of modern tanks.

fig. 21 |

fig. 22 |

The construction details of the metal frame carrying the tanks can be seen in Figure 23 and Figure 24.

fig. 23 |

fig. 24 |

It is a frame obtained by cutting, bending and welding steel bars and plates, using a process that seems completely manual with a very low level of industrialization. Since it was not made by stainless steel, the environmental protection of this frame was ensured by means of a paint treatment, just like for the tanks. This frame also included the fixing structure of the first stage pressure reducing valve including the low pressure air accumulation cylinder. The textile harness was finally assembled on the tanks holder frame and secured with metal rivets.

Compared to the current scuba units fixing plates and relative stainless steel or aluminum bands that firmly secure the tanks to the supporting structure in order to avoid any movement of the tanks themselves, whatever the overloads and the shocks applied, this frame worked as a sort of basket inside of which the tanks were placed and supported by the frame bottom end. The small integral clamps with bolts were used to prevent axial movements of the tanks but had a completely secondary structural function.

The tank valves and the special reserve device are illustrated in detail in Figure 25 and Figure 26, both for the single tank and for the double tank version.

The pneumatic connections among the various elements of the tank valves consisted of mechanical brass pipes, bent and weld brazed, a technique also used in the tank valves manufacturing of the first Scuba Cousteau-Gagnan units in the second half of the 1940s. Considering the position of these fittings, arranged in the lower part of the diver's back for better accessibility to the tank valve knobs and to the reserve device (see Figure 27), some areas of the fittings could be easily damaged by impact or contact during the dive and the handling phases of the scuba apparatus.

The most critical points were the weld brazed connection areas between the mechanical pipes and the solid body of the other components. From the photos below it can be seen that, between one specimen and another, the connection area between the reserve device and the brazed mechanical tube, a modification has been implemented to strengthen the area in question, thus avoiding the danger of cracking of the welded joint (clearly visible on the left pre-modification device).

fig. 25 |

fig. 26 |

fig. 27

The identification plates of the Tricheco were applied in correspondence with the clamps of the tanks or of the first stage cylindrical body as can be seen in Figure 28 and Figure 29.

fig. 28 |

fig. 29 |

These plates did not have the serial number of the unit but indicated the Pirelli headquarters in Seregno and both the Pirelli and the Galeazzi brands.

Another characteristic element of this device is the special quick connection fitting mounted on the connecting hose between the first and second stage (see Figure 30 and Figure 31). This component made it easier to prepare for the dive but also to transport and store the unit, allowing the diver to handle the full-face mask separately from tanks and harness.

fig. 30 |

fig. 31 |

Other components of this scuba model were also based on rather approximate and questionable technical solutions. One of these was undoubtedly the foldable snorkel (see Figure 32 and Figure 33 which show the snorkel in both extended and folded positions). The fact that this device was missing both in the unit that I had purchased in Portugal and in that owned by Angelo Silvestri, confirmed the doubt I had when observing the one still existing in the sample owned by Cesare Valle. That is, the plastic elbow fitting that connected the snorkel to the rubber body of the full-face mask, seemed to have a sealing lip on the outer side of the mask slightly wider than the hole on the rubber body.

fig. 32 |

fig. 33 |

This feature could have made this connection unstable with the risk of flooding the mask when the snorkel was subjected to some lateral stress. Furthermore, thinking of sealing the snorkel from the water inlet by simply folding it and holding it in that position during the dive certainly seemed a very simple but completely unrealistic solution, without considering the probable shape memory that the tube would have shown after a few maneuvers of bending and subsequent straightening. Therefore, we can argue that the users of this device have in some cases completely removed this device and somehow plugged the hole on the body of the full-face mask.

We close the technical concerns on this breathing apparatus by observing its pneumatic circuit for breathing. Normally, in regulators with second stages equipped with an "upstream" valve as in the case of the Tricheco, a maximum pressure relief valve is added between the first and the second stage whose function is to limit the pressure between these two stages when the first stage fails to guarantee perfect pneumatic sealing. This valve thus prevents the low pressure circuit from undergoing over-pressurization with the risk of dangerous breakages and explosions. In the Tricheco this relief valve is missing so it can be imagined that, in case of first stage leaking, a failure could affect the rubber hose placed between the first and the second stage. In the practical situations this rubber hose could have simply slipped out of the metal clamps.

What are the reasons why the Tricheco is so rare compared to other similar devices manufactured in the same period? Of course, we can only make assumptions about it, hoping that these are as logical and reasonable as possible. The main reason for this extreme rarity is probably due to the poor performances of this device compared to the typical double-hose models that had begun to spread among the Italian diving community from the mid-1950s onwards (mainly the Mistral regulators).

These poor performances, especially in terms of breathing hardness and ears compensation troubles, have been confirmed by Angelo Silvestri from Latina who actually used this device during his youth. Even the exhaust of the exhaled air through the perforated rubber hoods was quite annoying. The breathing hardness can be easily explained by the very low pressure downstream of the first stage which was not sufficient to effectively feed the second stage delivery valve, especially at greater depths. We also remember that the famous “Venturi” effect that was introduced first by the Mistral was not available in this unit and therefore the inspiratory effort of the Tricheco remained considerable hard in all conditions. If you look at the first stage of the unit that I purchased in Portugal, it can be seen that this does not have the cylindrical body typical of the original first stage (see Figure 34 and Figure 35). I can argue that this solution was introduced precisely in an attempt to solve or improve the problem of breathing hardness by increasing the first stage downstream pressure, a solution which among other things made it possible to eliminate the cumbersome and expensive air accumulation cylinder. low pressure air. I have not been able to find any documentary references on this different first stage version so far.

fig. 34 |

fig. 35 |

Even the ears pressure compensation was not comparable with the latest solutions available on the market, solutions among which the Pinocchio mask invented by Luigi Ferraro for Cressi in 1952 stood out, which made it possible to simplify the pressure compensation maneuver as much as possible. With the Tricheco mask you had to use the annoying "nose clip" or compensate with alternative maneuvers of dubious effectiveness. A further and decisive element to consider was the price of this device which, judging by the prices shown in the Pirelli catalogs, was more than double that of an oxygen rebreather, a very popular device in those years, also given the limited availability of new scuba models and which was often used for spearfishing. These performance limits and the high price resulted in very low sales numbers and consequently affected the number of units that are still in circulation today. We also add that this type of device, being based on many important components made of natural rubber, was inevitably very sensitive to the deterioration of these components which showed signs of aging and carbonization already after a few years of service making it necessary to scrape the unit. All these reasons and despite the fact that this underwater unit has remained in the Pirelli catalogs for more than 10 years, from the mid-1950s to the mid-1960s, explain why very few people in Italy and in the world are informed about this device.

This article is another small contribution of mine to the knowledge of those wonderful and unforgettable years of diving history as well as to the preservation of the memory of another small masterpiece of the genius and inventiveness of the great pioneers of that era.

_______________