In the context of the technological development of sport diving equipment, the mechanical decompression meter undoubtedly represents a milestone in the long journey that, starting from the tables with the use of dive timer and depth gauge, has led to the current era of digital dive computers.

In particular, when we are talking about mechanical decompression meters, the absolute protagonist worldwide was the DCP model, invented by Ing. Carlo Alinari in 1959 with the collaboration of his partner Ing. Victor Aldo De Sanctis and presented the following year at the general assembly of the Cmas in Barcelona. The two partners created SOS (Strumenti Ottici Subacquei or Underwater Optical Instruments), a company that, in addition to the production of mechanical decompression meters, became famous throughout the world for many other innovative and high-quality products.

The history of the DCP decompression meter and all the subsequent models produced by the Turin-based company until the early 80s, when the introduction of the first digital computers led to their decline and exit from the market in a short time, is effectively illustrated in the article by Andrea Campedelli published in the section "Let's talk about..." on the Luigi Fabbri website www.blutimescubahistory.com.

The thing that had always amazed me in researching information on these instruments and collecting various samples for my collection of historical diving equipment, was that almost all the major world manufacturing companies (Scubapro, Mares, Cressi, Technisub, etc.) had chosen to distribute the same SOS decompression meters under their own brand under license rather than marketing others designed and developed by them.

Probably the commitment and investments necessary to obtain competitive products compared to those of the Turin company were considered too high and unjustified from the point of view of the cost/benefit ratio.

The other reason could have been that all the research, development and manufacturing experiences on mechanical instruments alternative to the DCP had failed or had led to negative outcomes, effectively discouraging most of the diving equipment manufacturers from taking the same path.

The only exception I had been able to identify was that of a device developed and distributed starting in 1974 by the American company Farallon, a product identified with the trade name of Decomputer. Farallon, founded by the famous Ralph Osterhout, a brilliant character still in business with his Osterhout Design Group, and active for a few years from the early 70s until 1976 when it merged into the Tekna company, distinguished itself on the market above all for its famous DPV (Diver Propulsion Vehicles) which represented for all subsequent manufacturers of these devices the main reference for technical solutions, quality, performance and innovations. Farallon, however, was also involved in producing more conventional equipment such as masks, snorkels, fins (the famous Fara-Fin equipped with articulated and adjustable ankle straps), pressure gauges, depth gauges and dive compasses.

Coming back to the Decomputer, the rather surprising thing was that of this instrument, which was already quite difficult to find on the market of vintage diving equipment, there was also very little information available on the web or in books and commercial publications (catalogs, price lists, brochures, etc.). The only references I could find on the Internet are the two English-language commercial advertisements depicted in figs. 1 and 2.

As you can see, the Decomputer was distributed in two versions: the wrist one shown in fig. 1 and the one mounted in the dive console with pressure gauge and compass as shown in fig. 2.

Of these two versions a few years ago, I was able to buy, in one of the many auctions on the web, the Farallon console that seemed to have never even entered the water (see figs. 3 and 4).

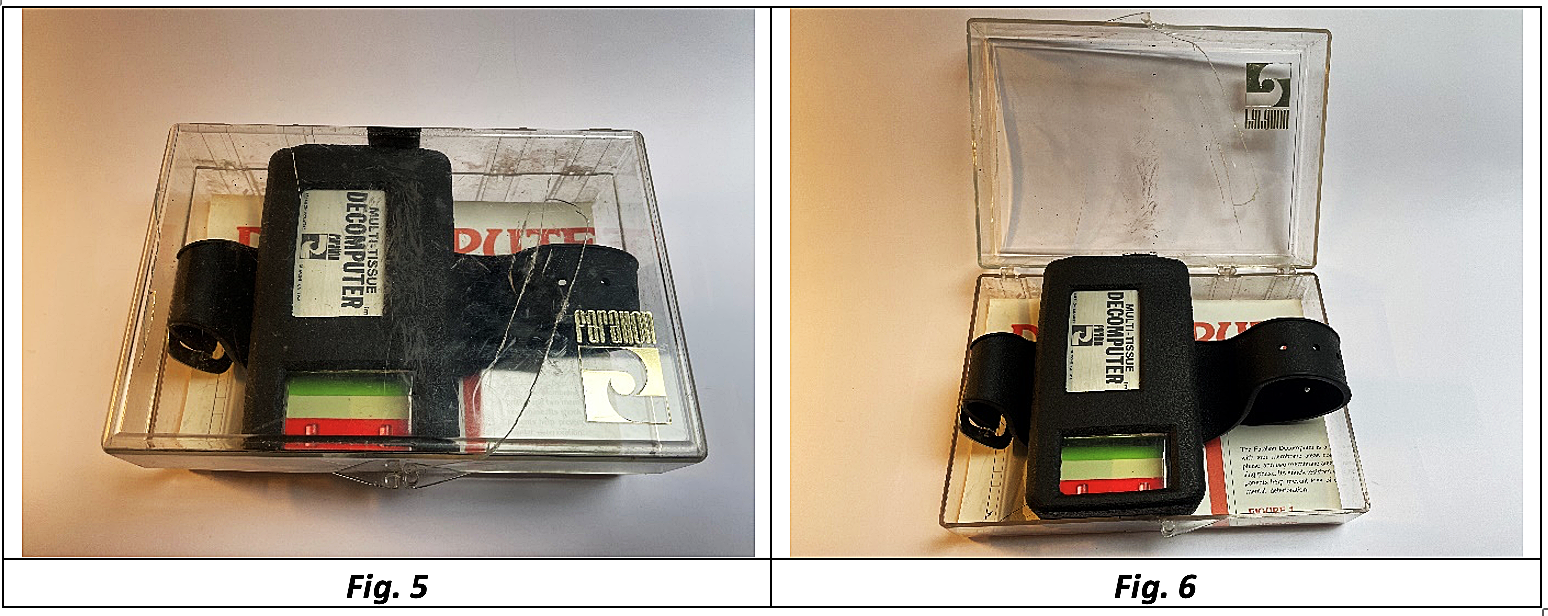

However, having not found anything significant that could better illustrate the functioning principles of the device, explain the almost absence of information about it and the rarity of samples available on the market of collector's diving equipment, for a long time I had not taken up the subject again. Then suddenly a few weeks ago I was lucky enough to find and buy on eBay a sample of the Decomputer in a wrist version and never used in water (perhaps a stock fund as shown in figs. 5, 6, 7 and 8).

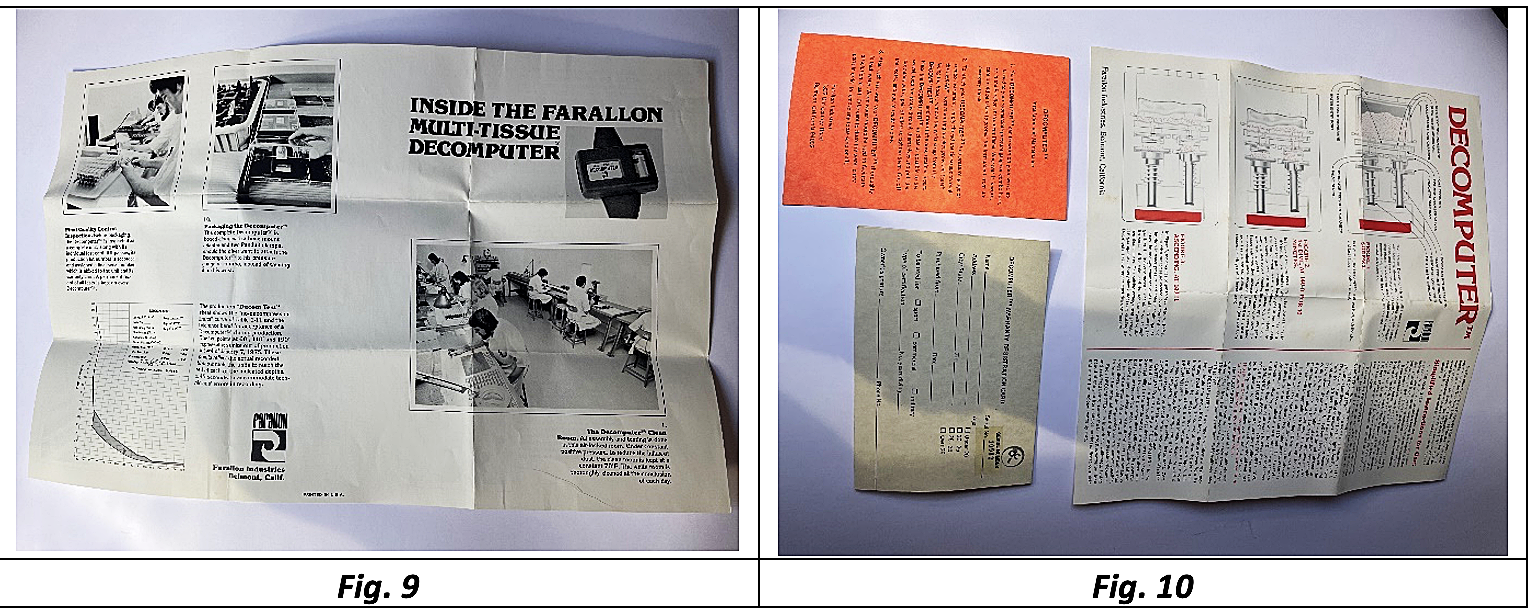

The most important thing, however, beyond the excellent condition of the unit in question, was that in this case the decompression meter was complete with the original container and all the documentation attached at the time of sale of the device (see figs. 9 and 10).

The study of this documentation allowed me to fill most of the gaps in terms of knowledge I had about this product and encouraged me to write this article with the aim of sharing all this information with fellow collectors and with all enthusiasts of this subject.

Meanwhile, an important premise printed in the product documentation and addressed to buyers of this device and that is: "The Decomputer should be used in conjunction with US Navy tables to safely plan your dives. It is not designed to be used as an alternative or as a substitute for them".

This statement was perhaps to be considered an important limitation of this model compared to its main competitor DCP SOS which for years had been used as a device capable of managing diving without necessarily consulting the diving tables by providing clearer indications with respect to the need for decompression stops and showing the recommended depths for the required stops. However, as we will see later in the article, these limitations were not the main cause of the commercial failure of the Decomputer.

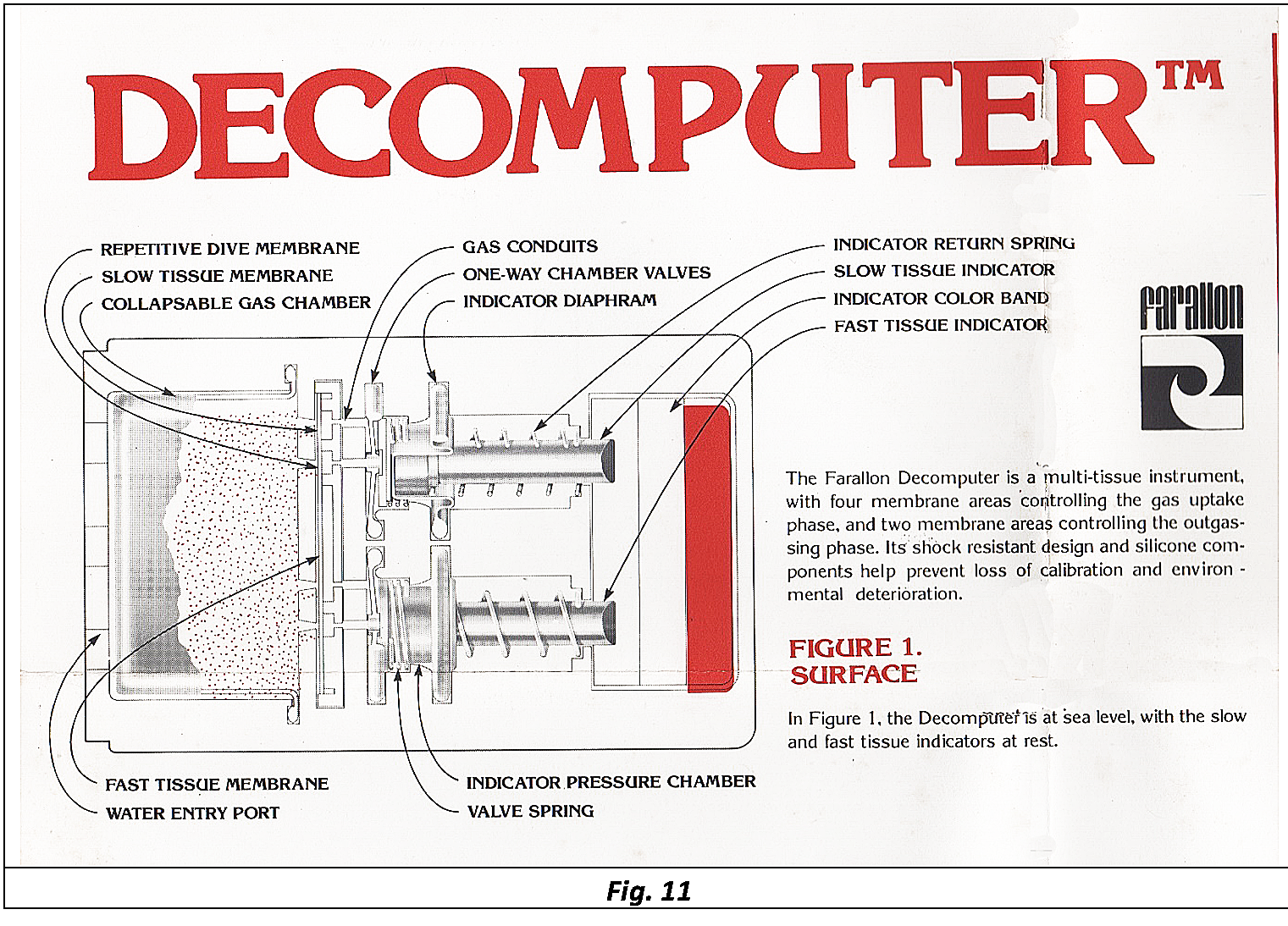

The information contained in the product documentation attached to the purchased unit allows us to accurately describe the operation of the decompression meter whose construction scheme is shown in fig. 11.

The operating principle of the Decomputer is not substantially different from that of the SOS DCP as it is based on the principle of delayed and controlled flow of gas through a semipermeable medium. In the case of DCP this medium consists of a ceramic plug, in the Decomputer the gas flow control system is made of a semi-permeable silicone membrane. Also in the Farallon decompression meter we find the elastic lung that contains the gas crossing the semipermeable medium in both directions depending on the phase of the dive (descent or ascent) but the system that indicates the condition of the tissues with respect to any decompression obligations is fundamentally different.

In the DCP this system is made by the classic Bourdon tube mechanism with needle and round dial while in the Decomputer two black indicators move linearly over a three-color window with the following meanings: green-no decompression obligation; white-attention zone; red-obligation to decompression. The two indicators represent the two different tissue compartments on which the operating principle of the instrument is based: the left one takes into account the "slow" tissues while the right one represents the "fast" tissues. The different flow velocities representative of the two tissues were obtained by increasing or decreasing the passage surface of the support base on which the membrane was rested and fixed. The device was also able to reproduce a lower gas passage rate during the ascent phase compared to that typical of the descent phase.

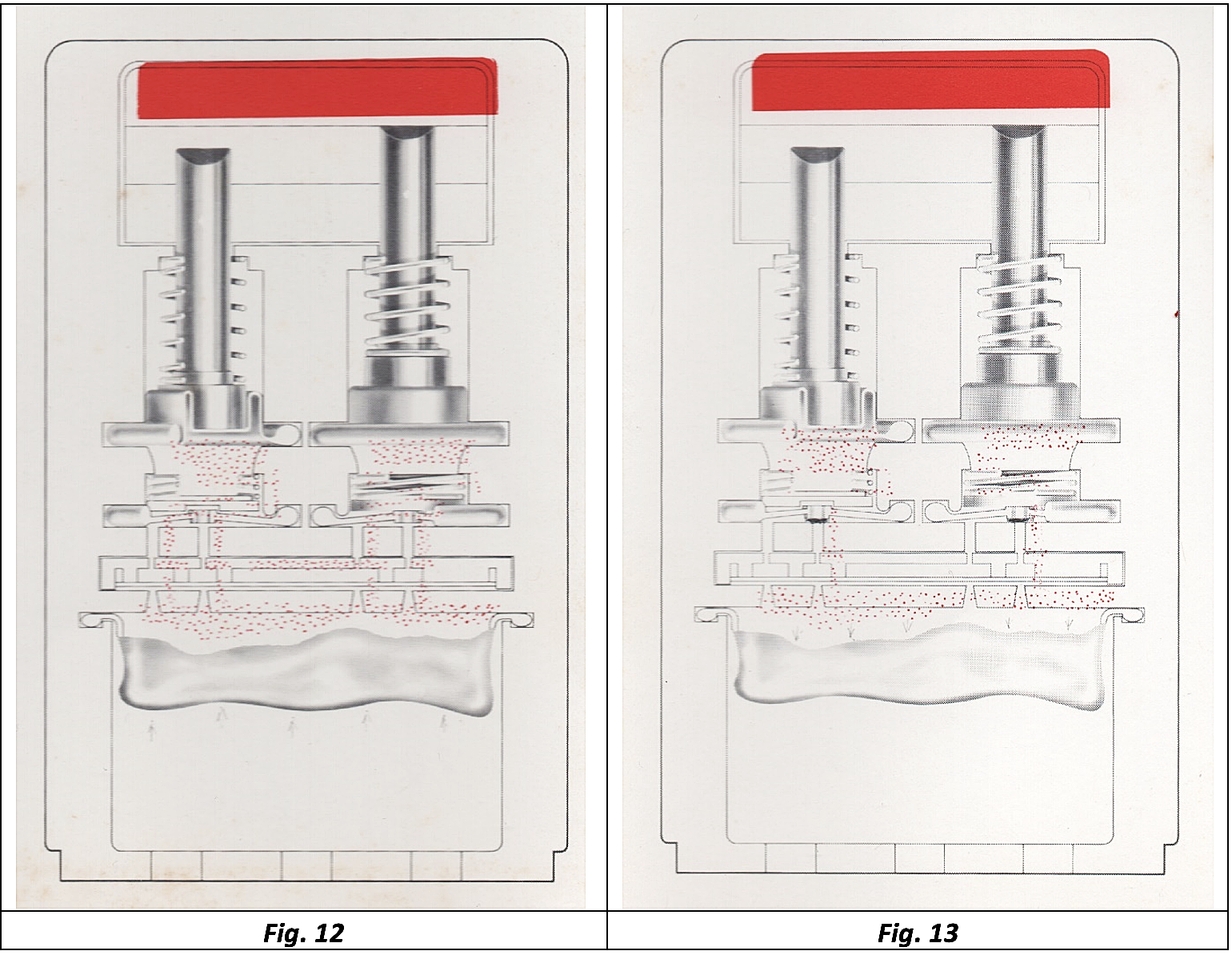

This mechanism simulated the typical tissue desaturation behavior at the end of the dive and allowed repetitive dives to be safely managed. In this regard, two one-way valves were mounted inside the instrument (one for each tissue taken into consideration) which opened during the descent and closed during the ascent, thus varying the total surfaces of the membrane through which the gas flowed and therefore the corresponding outflow velocities. This principle is well illustrated in the cross-sections of figs. 12 (descent) and 13 (ascent).

The other information element that I was able to draw from the documentation attached to the unit I purchased and that I think it is important to share with collectors and enthusiasts is the complete description of the entire production process of the Decomputer and the equipment used for the assembly, the calibrations and the final testing of the decompression meter. Normally this information is not disseminated and available to the public by manufacturers and I personally had never found anything like it on this type of equipment until now. I therefore thought that reporting this information within this article was of interest to enthusiasts of the subject.

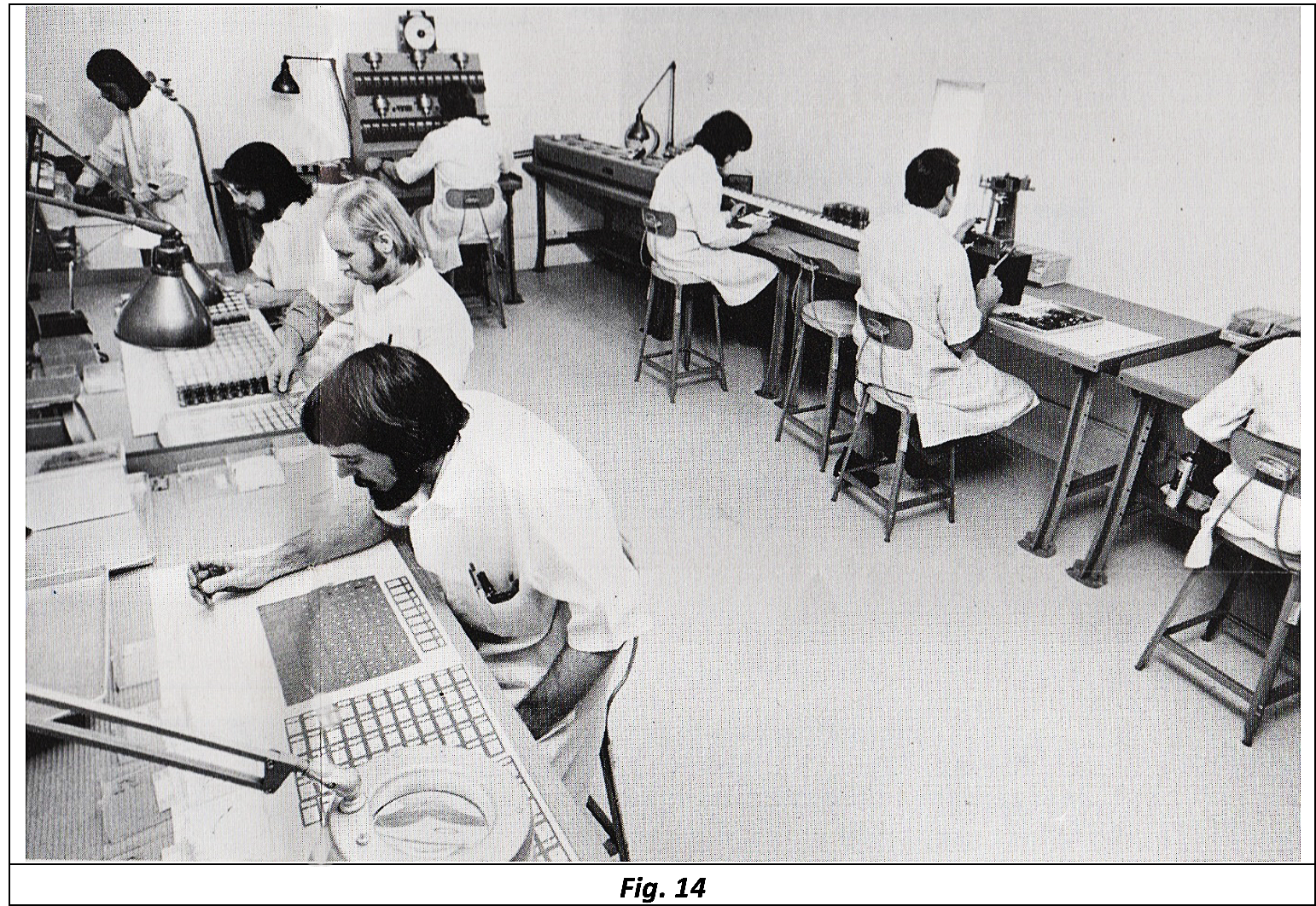

From reading the documentation it can be understood that Farallon dedicated large resources and considerable investments to this product (the documentation states that the cost of the assembly and testing equipment had been 110,000 dollars which was still a good amount in the mid-70s) setting up a dedicated assembly and testing department that was housed inside a "clean room". This type of environment (see fig. 14), by maintaining a slight internal pressurization of the room, prevented dust or other contaminants normally present in the atmosphere to enter the room so depositing on the components of the equipment during assembly, compromising their operation and repeatability of performance. This type of infrastructure is now a standard for every manufacturing-assembly process of electronic and precision equipment.

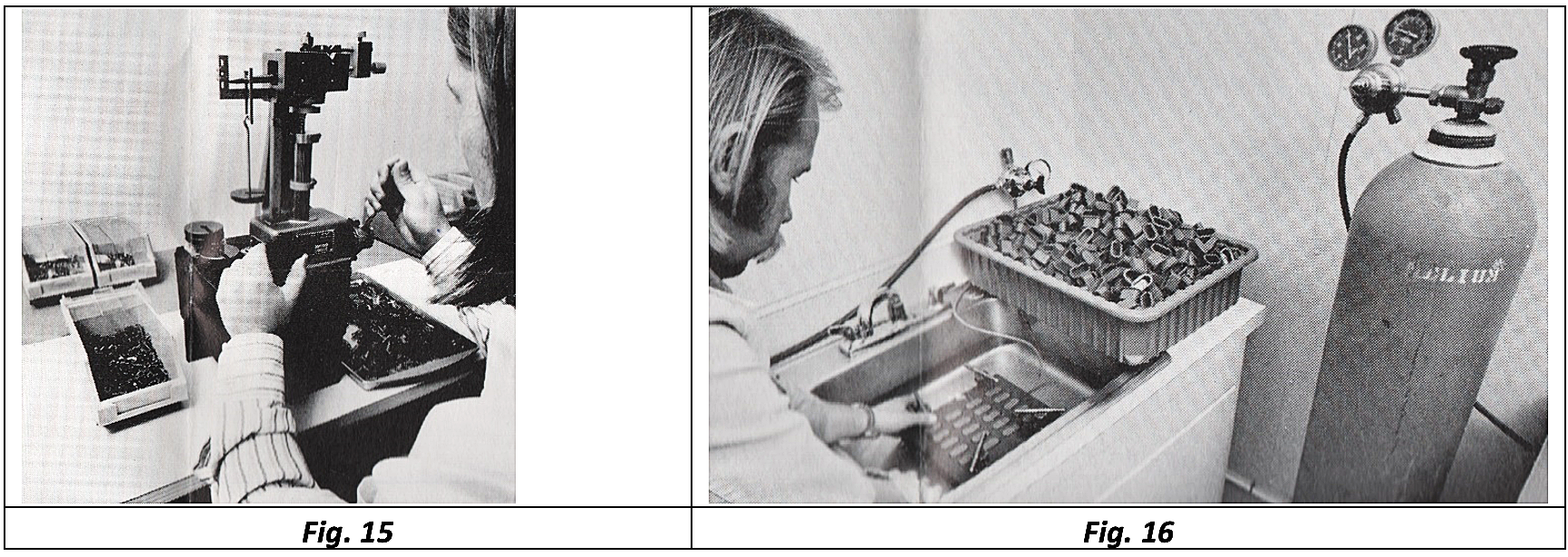

The assembly process of the Decomputer began with the verification of the most important components of the device, including the pre-charge springs of the pneumatic chambers connected to the saturation indicators (which had to have the force/stroke characteristic within the tolerance limit of ±1.25 % compared to the nominal value) and the flexible silicone rubber lung (which had to show no pneumatic leakage). For greater effectiveness in detecting any leaks, helium was used instead of air. The two phases described here are shown respectively in figs. 15 and 16.

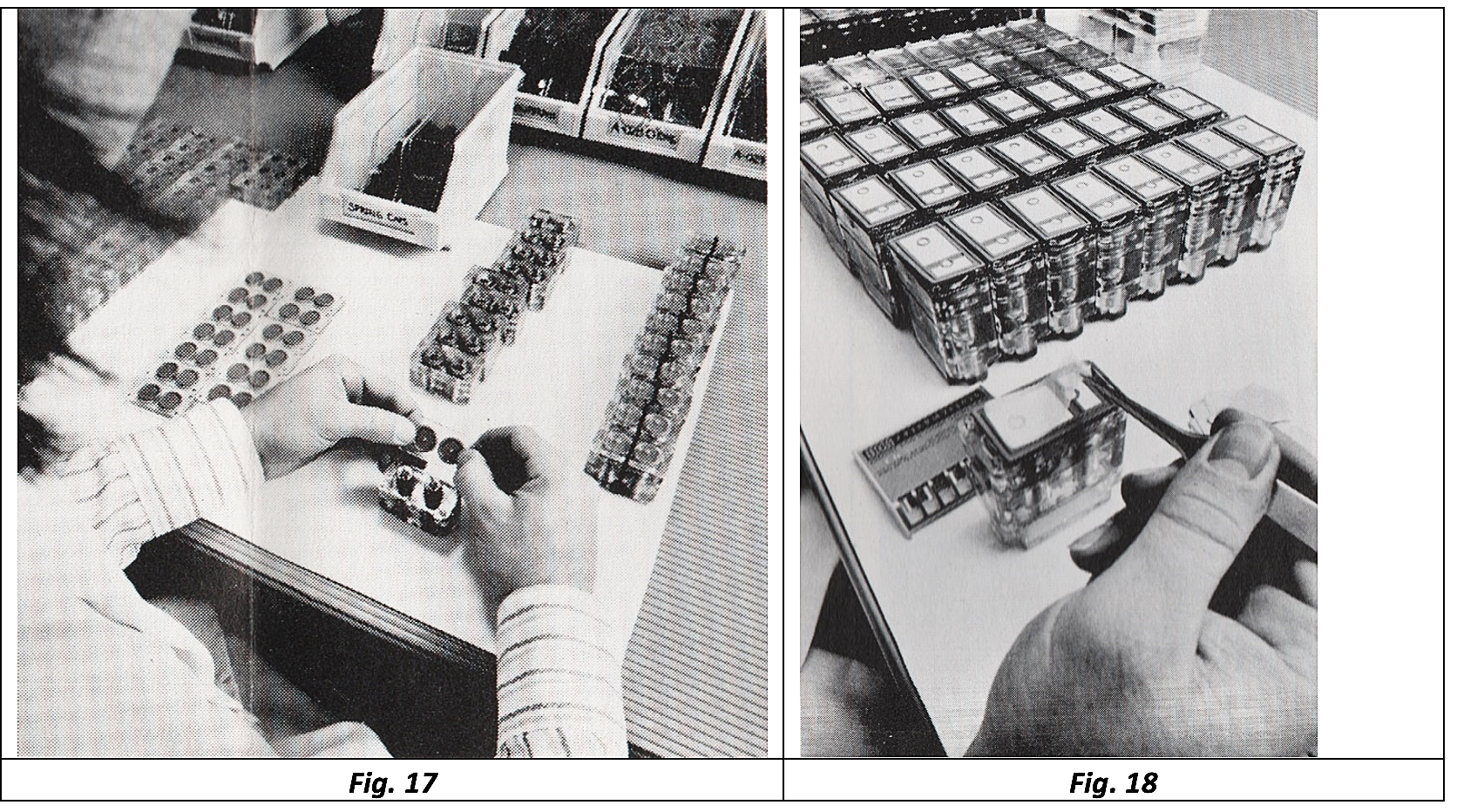

The assembly sequence continued with the installation of the one-way valves responsible for the variation of the gas outflow velocity between the descent phase and the ascent phase (see fig. 17) and with the mounting of the semipermeable membrane on its support base with pre-drilled surfaces of different areas (depending on the different gas outflow velocity that had to be realized). The handling of this special membrane (see fig. 18), whose thickness was in the order of two hundredths of a millimeter, was particularly critical, especially since it was very susceptible to electrostatic charges and therefore had to be treated with a special polonium-charged reducer.

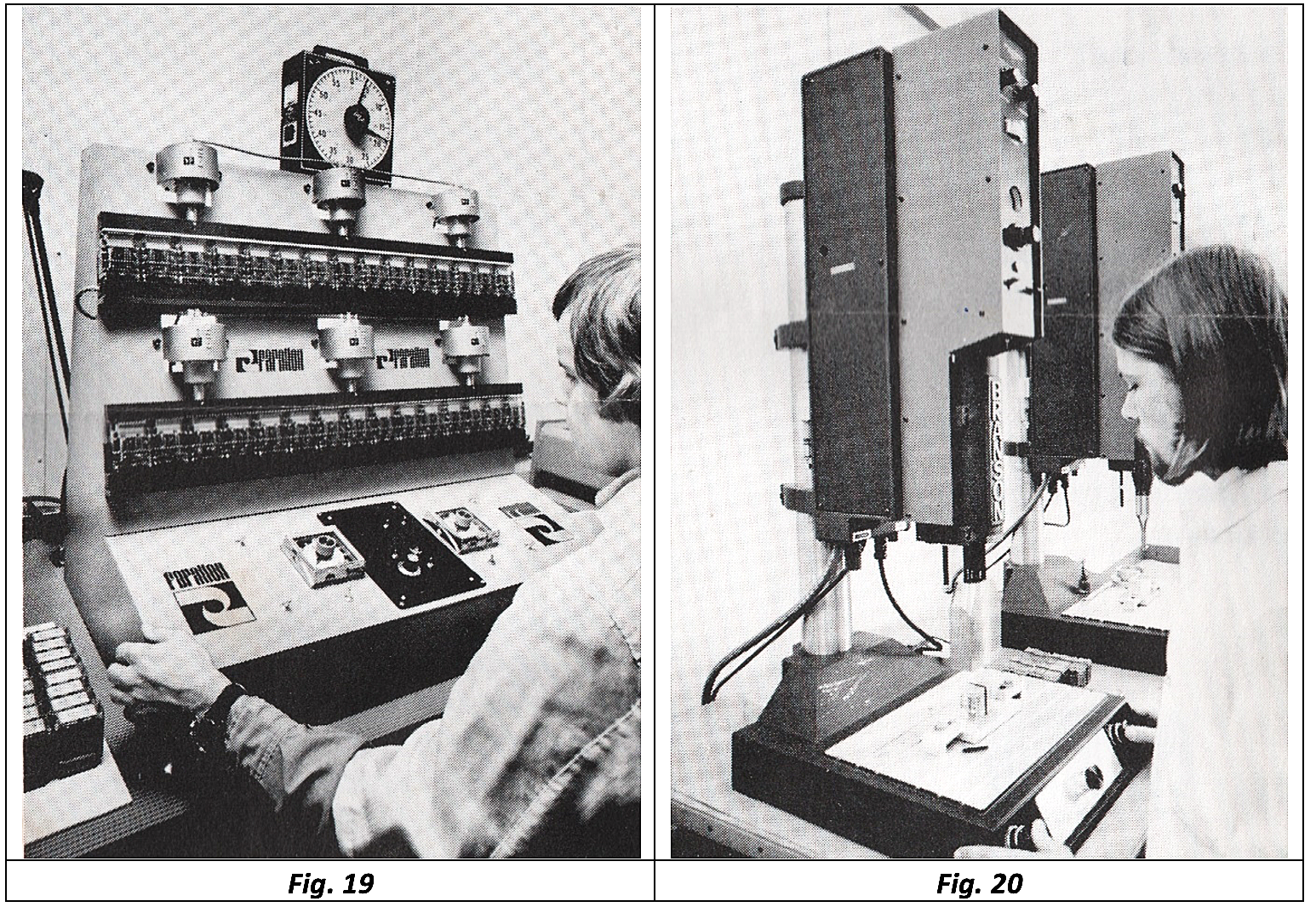

Since the behavior of the membranes realized the "heart" of the device, they were subjected to a specific test and calibration process in order to obtain gas outflow rates within specific tolerances. This process was carried out using a special computerized bench (see fig. 19). The assembly sequence ended with the ultrasonic welding of all the elements of the device to make a single polycarbonate (Lexan) block that ensured the extreme integrity of the assembly and the complete sealing of the internal components with respect to the environment (see fig. 20).

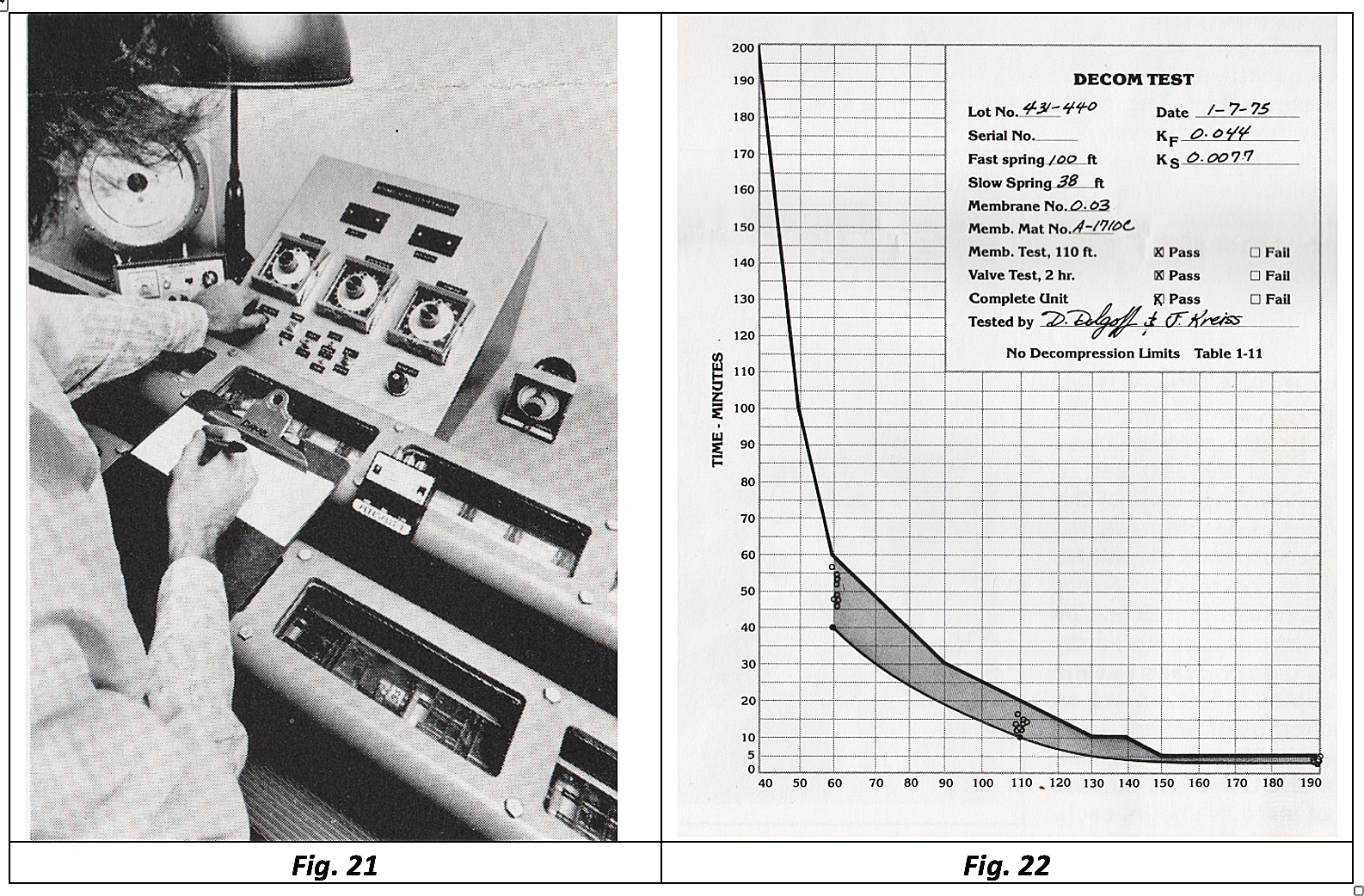

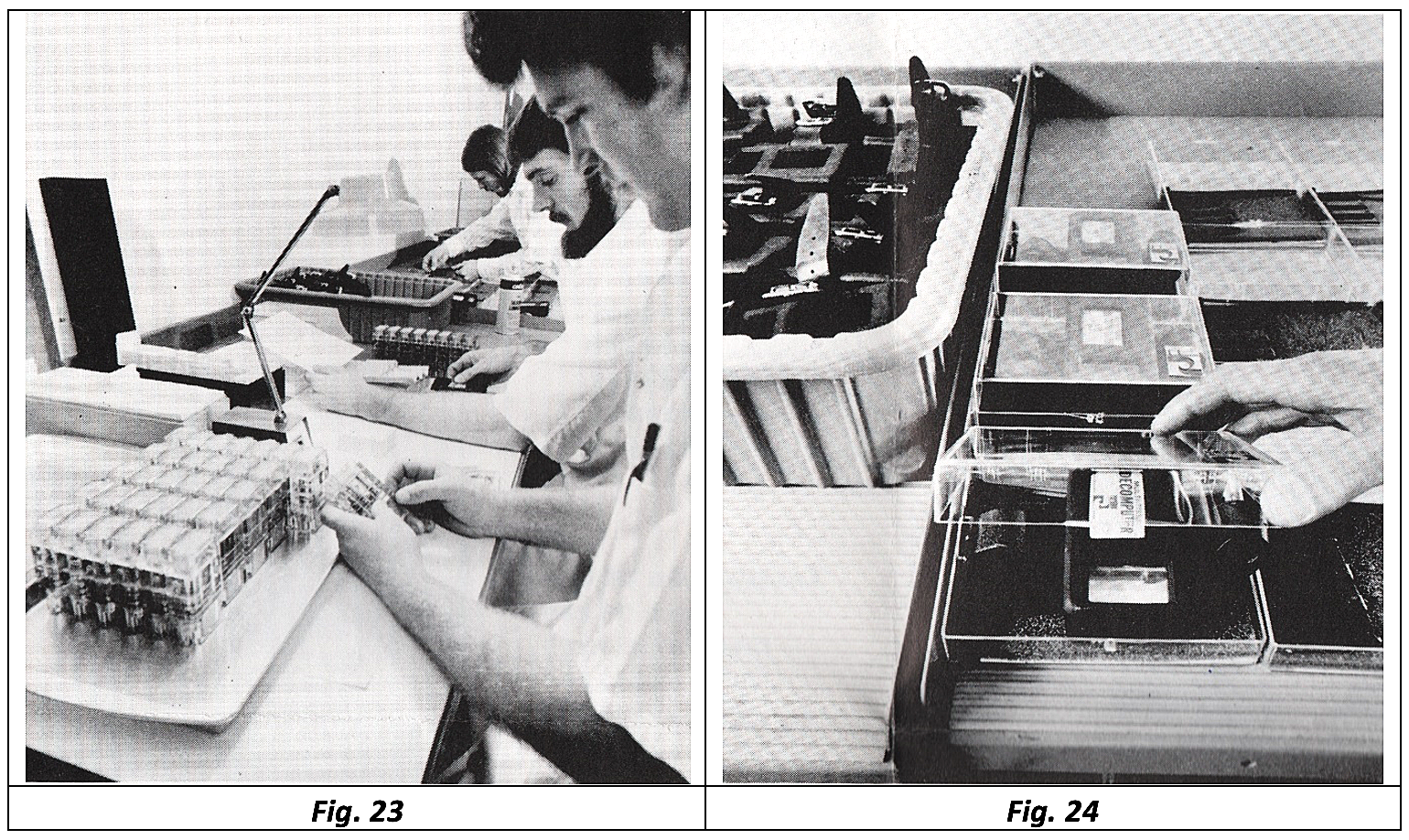

After assembly, the units were tested using the special computerized test bench shown in fig. 21. In this bench, the instrument was subjected to three separate simulated dives, the first at 60 feet (18 meters), the second at 110 feet (33 meters) and the third at 190 feet (58 meters). The time needed to reach the red zone (start of decompression) was compared with the corresponding limit of the US Navy tables. To take into account the inevitable tolerances on the reading of the various units, Farallon defined a range of acceptability that was in any case more conservative than the values prescribed by the tables (see the gray area of fig. 22). Units that showed higher decompression limits than those in the tables were permanently scrapped.

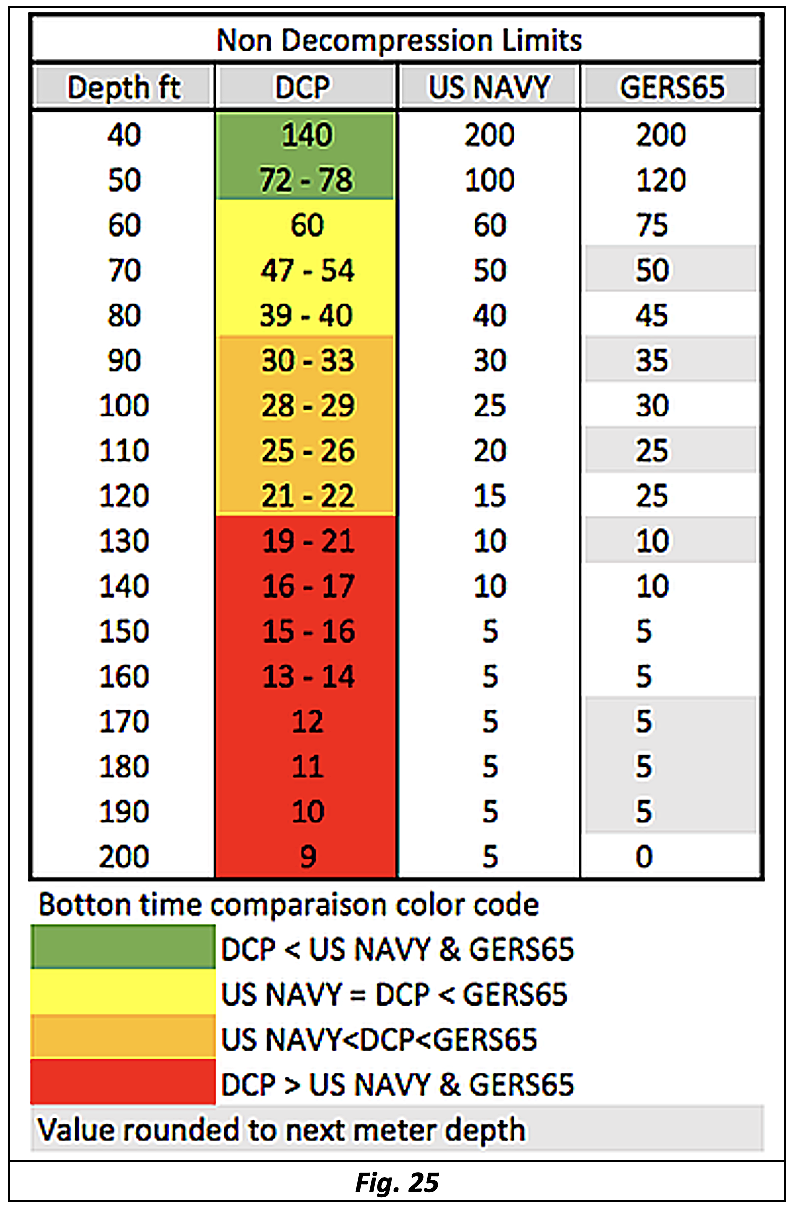

After testing, the units were subjected to the final quality control in which, in addition to the final inspection, each unit was provided with a serial number and all the enclosed documentation. Finally, all test and calibration results were recorded for any future need (see fig. 23). Finally, the unit and all the enclosed documentation were placed inside the special transparent box with which the Decomputer would then be shipped to end customers and dealers (see fig. 24).

Now the last question to be answered remained, namely: why was this device, despite its declared performance, manufacturing quality and ease of use, so uncommon on the market and is almost impossible to find today?

More research was needed on the subject. A document that I found on the net and that provided me with a first useful indication on the history of the Decomputer was the famous publication "Proceedings of Dive Computer Workshop" containing all the articles of the studies presented as part of the American Academy of Underwater Sciences Dive Computer Workshop held at the U.S.C. Catalina Marine Science Center Santa Catalina Island, California from September 26 to 28, 1988. This workshop remains one of the largest events in the world organized on the theme of the development of diving computers.

In particular, one of these works entitled "The History of Decompression Devices and Computers" by Karl E. Huggins of the University of Michigan Underwater Technology Lab, among the various devices examined, dedicated half a page to the Farallon Decomputer. According to what is mentioned in the article, this device, together with the DCP and other similar decompression meters, had been the subject of specific tests by researchers Howard, Red, K. Schmitt and P. Huisveld of the Scripps Institution of Oceanography in La Jolla, California, who had published in 1975 a specific article entitled "Preliminary Observations on the Farallon Decomputer". During these tests, the device was found to be less conservative than the US Navy limits not only at greater depths (as well as for the DCP SOS) but also for shallower depths (as opposed to the DCP).

According to this article, the Australian Navy had also tested the device finding it too permissive and susceptible to strong mechanical deterioration (Flynn 1978).

Among other things, this article also seemed to confirm the hypothesis anticipated in the previous pages, namely that probably most of the companies producing diving equipment had in fact been advised against undertaking design and research work on alternative products to the SOS DCP, given the negative experiences of all those who had ventured for more than twenty years into the development of mechanical decompression meters.

Limiting ourselves only to devices with purely mechanical functionalities, the article reports the experiences of the Decomputer Mark I developed by the company Foxboro in 1955 and immediately afterwards also presented to the NEDU (Navy Experimental Diving Unit) for evaluation, of the analog computer designed in 1962 by the DCIEM (Defense and Civil Institute of Environmental Medicine) and of the mechanical decompression meter produced as a prototype by General Electric in 1973, whose operation was based on semi-permeable silicone membranes exactly like for the Decomputer Farallon. Given the time contiguity of the two projects, I believe it is quite likely that the experiences and technical solutions developed for the General Electric decompression meter formed the basis for the technical choices then adopted in the Farallon Decomputer.

If important research institutions, government organizations and large world-class companies had failed to find technically and commercially viable solutions, imagine if diving equipment manufacturers could be encouraged to go down the same path.

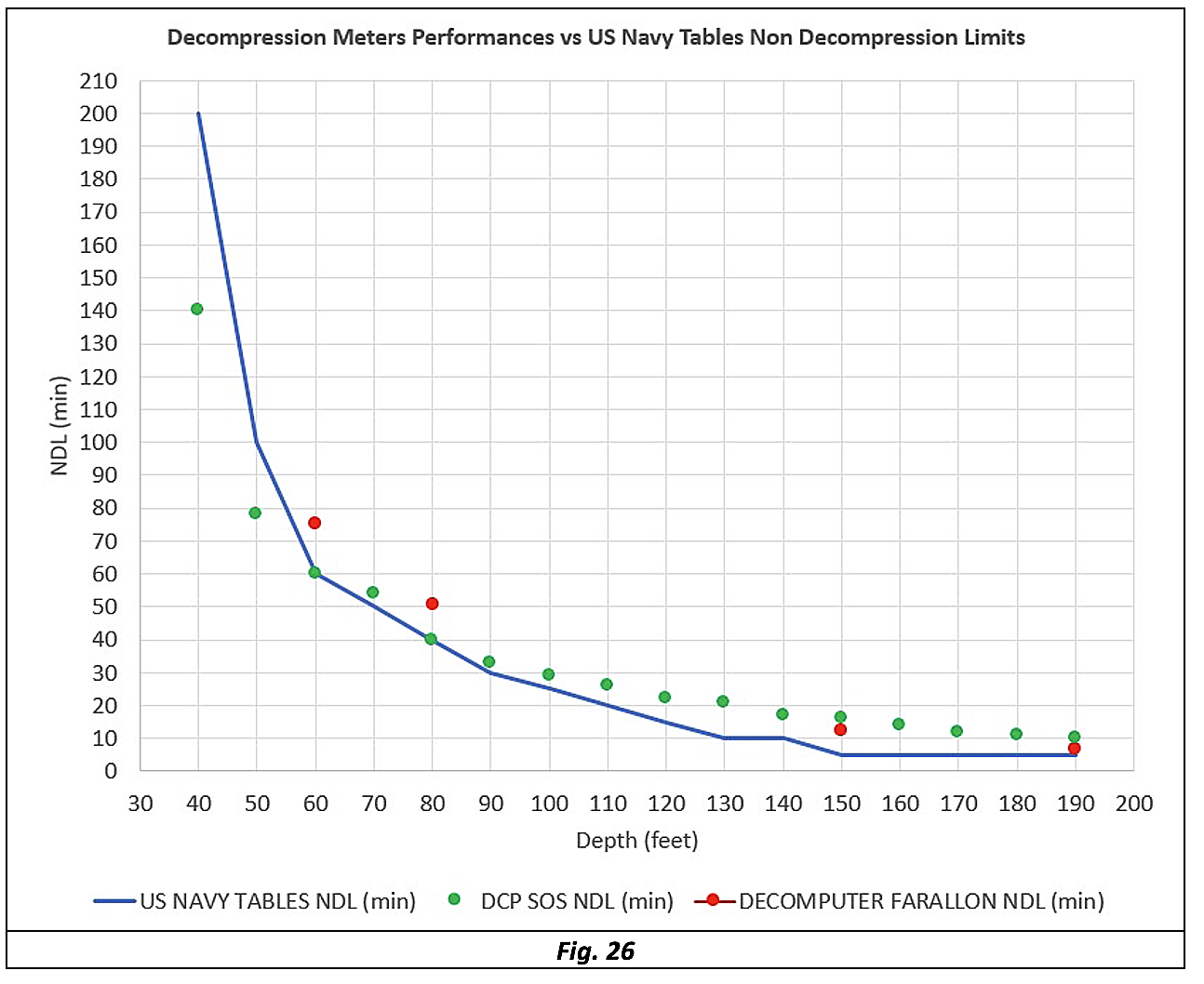

To make a comparison between the real performance of the Decomputer and that of the DCP, I used the data from specific tests carried out on the Italian decompression meter and available on the web (see fig. 25) with the few data reported in the workshop article and thus developed the graph shown in fig. 26.

Looking at this graph the following elements can be derived:

- Both the DCP and the Decomputer were more permissive than the US Navy tables for depths greater than 60 feet (18 meters)

- For depths greater than 150 feet (45 meters) the differences in readings between the two instruments were minimal

- The DCP was found to be more conservative than the U.S. Navy tables for depths of less than 60 feet (18 meters). The Decomputer, on the other hand, continued to be less conservative than tables even for this depth range

- Since all Decomputer units were tested for alignment with the US Navy tables (never less conservative than the tables as shown in fig. 22), the fact that the readings during the tests were very different from those during factory testing would seem to confirm the conclusions of the Australian Navy that the behavior of the instrument was extremely sensitive to use or perhaps to some other environmental condition (temperature ?).

I then tried to find more information by consulting some of the main forums on the net dedicated to historical diving and I found the testimony of an old Farallon employee who was working in the "Customer Service" department and who remembered the huge amount of these units returned by customers for various operating problems. For this reason, Farallon's service technicians had ironically renamed the Decomputer "Decomposer". Because of this situation, Farallon decided to stop the production of this device and to proceed with a general recall campaign with the return to customers of the entire amount paid for its purchase.

This decision, which would have led to serious economic problems for the company and the interruption of its activities (then partially resumed within the new Tekna company), is the main reason why these instruments are very rare and difficult to find even in the market of historical diving equipment.

For what has been said in the article, we can certainly conclude that the Farallon Decomputer will never be remembered as an instrument that has significantly influenced the history of sport diving, but the events of this device are still an important testimony of how the technological evolution in this sector has in some way also profited from the many technical and commercial failures that occurred during the evolution of diving equipment.

|

|

________________