Among the numerous innovative and original products launched on the market by Scubapro we need to remember the “Visionaire” mask (see Fig. 1 and Fig. 2), sold by the US company in the period between 1965 and 1970.

|

|

| fig. 1 | fig. 2 |

In that initial period of the company’s life, the two Scubapro’s founders, Dick Bonin e Gustav Della Valle, did not economize efforts and initiatives to catch the attentions and the preferences of the wide north American scuba diving customers base by differentiating themselves, from the numerous and strong competitors, for innovation capacity and product quality. This strategy included also the possibility to purchase patents or products developed by private inventors or by small manufacturers, then improving them as necessary, put them in mass production and finally start their distribution with the Scubapro brand. This type of approach was followed also for the “Visionaire” mask, which was invented by the US citizen Charles Hubbel Hawley (1921-1990) in 1956 and patented in 1957.

The most innovative element of this Scubapro full face mask was doubtless the demand type air supply device integrated within the mask itself. This device used, as pressure balancing diaphragm, the whole mask glass installed on a flexible frame. This frame was part of the mask rubber body. During the inspiration phase, the pressure gap between the external and the internal glass faces, produced an inward movement of the glass. This movement was capable to actuate a normal air supply “downstream” valve installed in the center of the upper mask body (see Fig. 3 and Fig. 4).

The mask could be fed by a standard regulator’s first stage (Scubapro proposed the classic MKII first stage model, as shown in Fig. 5, or the MKV model), linked to scuba tanks worn by the diver, or by a surface air supply unit. This latter could have been made by a group of high pressure air tanks or by a compressor, through a low pressure hose (see Fig. 6). This configuration, well known as narghilè (or also hookah in the USA), was preferred to the SCUBA unit for long duration and shallow waters professional jobs. The history of Hawley and of his mask is told by his daughter Samara in the n° 54 of Historical Diver, the official magazine issued by HDS USA.

|

|

| fig. 3 | fig. 4 |

|

|

|

| fig. 5 | fig. 6 |

Surely the idea of using the whole mask glass as an air supply demand valve pressure compensating diaphragm looked to be ingenious and, reading the Hawley daughter’s article only, nobody would have put in doubt the Hawley’s full ownership of such idea. The article indeed is written by the Hawley‘s daughter who remembers her father with a mix of love and admiration for his inventor’s career, distinguishing most of his entire life. Off course, this article cannot be considered fully objective and complete of references to other inventors of manufacturers of similar equipment. In reality, as frequently happened during this diving industry historical period, still pioneering for some aspects, the several solutions put on the market were developed starting from other people’s ideas and patents and adding variants or specific devices capable to improve their performances or to solve issues intrinsic in the original solution. In the case of the “Visionaire” mask, the main references for Hawley in the years when he decided to work on this project were the following:

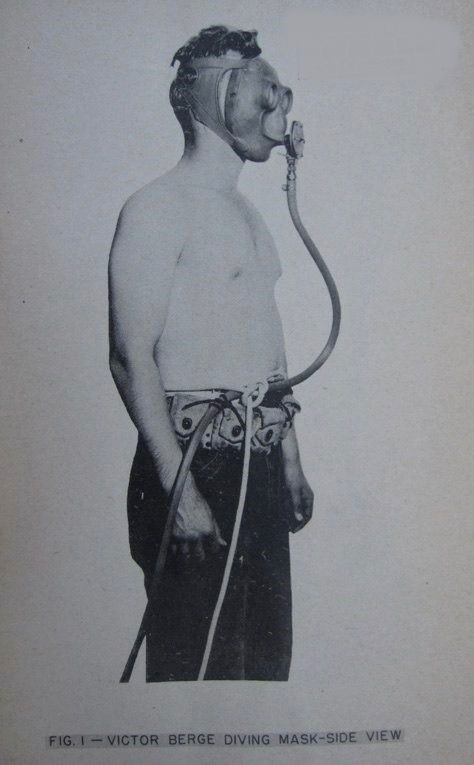

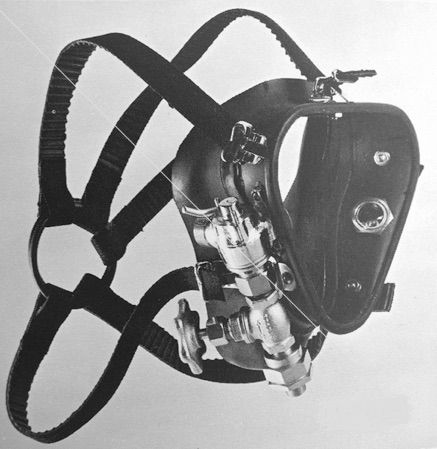

- Binocular full face mask manufactured by the Ohio Rubber Company for the U.S. Navy and based on the Victor Berge‘s patent (see Fig. 7 and Fig. 8). This system, modified from the patent’s scheme and widely used by the U.S. Navy during the Second World War, was fed from the surface through a low pressure pump.

|

|

| fig. 7 | fig. 8 |

- Professional DESCO “Jack Browne” full face mask, working through a continuous air flow feeding system. This mask (see Fig. 9 and Fig. 10) was designed for the U.S. Navy needs as well, and used during the Second World War in shallow waters operations, as an alternative to the classic hard hat diving gear, much more bulky and complex to be operated. Thanks to its simplicity and effectiveness this mask remained in production until the ’80 years. As you can see from the pictures below this mask, with its peculiar triangular shape, included a connection with the surface air feeding hose and an air flow metering and shut-off valve, installed on its right side and an exhaust valve, placed on its left side. The mask could be equipped with a voice communication system, similar to that used by the hard hat divers.

- Hydro-Pack manufactured by Scott Aviation. This full face mask, sold starting from 1954, in reality was a complete SCUBA unit including a single hose double stage regulator, an air tank with its valve and a harness (see Fig. 11 and Fig. 12).

And finally there was the SCUBA unit for excellence, namely the Cousteau-Gagnan Aqualung which, on the middle of the ’50 years, especially thanks to the strong commercial distribution of this product by the U.S. Divers, had become very popular in North America. It constituted the natural reference point for any inventor having something to propose as an alternative to this famous unit. The typical American culture of the “self-made man” was in its full deployment phase with strong encouragement to anyone provided with intelligence and toughness in inventing and building equipment, machines and devices, frequently using other product’s parts and components. -

fig. 9 fig. 10 -

fig. 11 fig. 12 Magazines like Popular Mechanics and Popular Science remained very famous with instructions and procedures to even home-make his own SCUBA unit, by using oxygen mixing and feeding systems for pilots of Second World War military aircrafts. At that time, these devices were available at very low cost as scrap parts.

The inventors often tried to realize products with similar or even better performances of the equivalent ones available on the market but with much lower costs. Indeed, in both the cases shown before of masks provided with an underwater breathing system, the cost of these devices was much higher than the average customer’s capability and, therefore, there was a strong interest among the outdoor activities lovers in finding equivalent solutions, though of handicraft type, but at much lower prices. Charles Hubbel Hawley in particular, was interested in finding a solution for an innovative mask allowing a natural earthly breathing mode, namely by the nose, conversely of the Aqualung, requesting a quite unnatural breathing mode through the mouth only. Therefore, the best solution would have been a common mask covering eyes and nose but leaving the mouth outside.

This configuration indeed was that Hawley proposed in his patent request n° 3.009.462 filed on November 1st 1957 (see Fig. 13 and Fig. 14) and released by the US Patent Office on November 21st 1961 with the name of Breathing and Viewing Apparatus. -

fig. 13 fig. 14 As you can see in the pictures above the air supply demand valve of this mask was a “tilt model” and “upstream” type valve installed in the central lower body of the mask itself. The actuation of this valve, controlling the pressurized air coming from a dedicated hose, was performed through the movement of the mask external frame, including also the glass hinged on the mask’s upper area. We have so found the application of the idea of using the mask’s glass as air supply demand valve pressure balancing diaphragm and, therefore, we could assign to Hawley the ownership of this idea.

In reality this solution has been already proposed before by another US inventor and namely by William B. McLean through his patent request n° 2.882.897 filed on August 15th 1955 and released on April 21st 1959 with the name of Breathing Apparatus (see Fig. 15 and Fig. 16) -

fig. 15 fig. 16

On a closer inspection, this patent request was very similar to that presented by Hawley, having the same air supply demand valve actuation principle through the mask’s glass. This glass, installed on the mask’s rubber body, was designed to produce its inward rotation during the inspiration phase so pushing on the small piston controlling the demand valve air flow, as shown in the pictures above.

The main differences were in the air supply demand valve position, located on the mask’s upper area in the McLean‘s patent, and in the valve’s arrangement, still of “upstream” type but with an axial instead than a side movement. As you can see McLean in his patent also considered the solution with a complete full face mask, provided with a duck-bill type exhaust valve, a configuration not included in the Hawley’s patent.

It looks quite clear now who was the real owner of the mask’s glass to be used as air supply valve pressure balancing diaphragm. Unfortunately, we have found also the patent request of the Italian Roberto Galeazzi Jr. (1911-1994), son of Roberto Galeazzi Sr. (1882-1956) the founder of the homonym company and the inventor of the underwater observation device successfully used also by SO.RI.MA., during the gold ingots recovery in the famousEgypt carrier ship salvation campaign.

Galeazzi Jr., owner of more than 30 specific patents covering underwater and hyperbaric systems, filed the patent request n° 2.882.895, at the US patent Office, on September 26th1956 and obtained the release of his Open-Cycle Breathing Apparatus on April 21st 1959, namely the same day of the Mclean’s patent release! And even the Galeazzi’s patent number (2.882.895) resulted to be two numbers before the number assigned to the McLean‘s one (2.882.897).

This patent (see Fig. 17), together its complementary n° 2.874.692, filed on September 14th1955 and released on February 24th1959 (see Fig. 18), constitutes the claims base of the “Tricheco” SCUBA unit distributed by Pirelli in Italy from 1955 to 1966 (see Fig. 19 and Fig. 20).

In the Galeazzi‘s request it is indicated that the Italian patent was filed on October 1st 1955, precisely one and a half month after the McLean‘s patent presentation date. Now it looks quite unlikely the two inventors, having filed their patents in two distinct country and almost at the same time, would have copied each other. This conclusion looks justified, also considering the very short time available to develop solutions technically different but based on the same principle, as proved by the analysis of the two patent requests. It is also possible the two inventors were inspired by previous applications using the same principle.

Analyzing the Galeazzi‘s patent, we can realize that this solution, when compared to those of the McLean‘s and Hawley‘s patents, although maintaining the idea of the mask’s glass to be used as air supply demand valve pressure balancing diaphragm, had several elements differentiating it from the two American inventor’s patents. Namely, these elements were the following:

- The Galeazzi‘s mask was developed as full face mask covering nose and mouth and, therefore, it had a higher complexity level with respect to the Hawley’s and McLean’s original ideas.

- The Galeazzi‘s mask glass rotation hinge was located in the mask’s lower area (in the same position of the “upstream” type air supply demand valve body) whereas in the McLean’s and Hawley‘s solutions this hinge was located in the mask’s upper area.

- The Galeazzi ‘s mask worked through a double stage pressure reducing system, with a first cylindrical pressure reducing stage aligned and coupled with the tanks (see Fig. 18 and Fig. 20) and with a second pressure reducing stage installed in the mask’s central and lower area (see Fig. 17 and Fig. 19). This configuration was much more realistic of the original ideas from McLean and Hawley, which allowed a single pressure reducing stage located inside the mask. After all the ideas of the two US inventors were based on the knowledge at that time still not including two stages single hose regulators. When the two inventors started working on their mask solutions, this type of regulator was still in its embryonal phase in the USA and would have become popular not before the beginning of the ’60 years.

-

fig. 17 fig. 18

-

fig. 19 fig. 20 Whereas we do not have any information about practical applications and further developments of the McLean’s solution, Hawley manufactured several prototypes and variants of his mask but, unfortunately, he never succeeded in demonstrating the goodness and the technical feasibility of the original idea shown in the patent. This idea, as we can remember, had the aim to produce a very simple, cheap and user-friendly mask. Some pictures of these prototypes, taken from the Hawley‘s daughter Samara private files, are shown in the HDS USA article, previously mentioned.

Analyzing the differences between the final configuration of the Scubapro “Visionaire” mask, as distributed and sold to the customers, and that of the Hawley‘s patent idea, we could here speculate on the several issues the US inventor had to solve during the development phase and the modifications he introduced to eliminate or reduce such issues: - The air supply device consisted in a tilt valve stem, secured to the mask’s fixed frame and installed inside of a tubular body. This body was in turn fixed to the mask’s moving frame, which was hinged to the mask’s upper area. The side movement of this tubular element, pushing on the tilt valve stem during the inspiration phase, caused its rotation from the sealing base so starting the air flow inside the mask. The application experiences of this valve type in other breathing devices at that time (i.e. the first series of the Mares Air King “S” double hose regulator), had demonstrated this valve was not suitable for a high pressure air feeding directly from the tanks, the same solution also supposed in the Hawley‘s patent, for the following reasons:

- The tilt valve soft sealing material (normally rubber) was rapidly deteriorated with the increase of the air pressure acting on the sealing material itself. The life of this part proved to be acceptable for air pressure values of few bar (and therefore for double stage regulators) but definitively too short for the high pressure values existing inside the tanks. To solve this issue Mares, in the Air King “S” double hose regulator, had to add a first stage pressure reducing stage upstream of the tilt valve.

- In case of high pressure feeding the valve, the air flow generated when the tilt valve opened was too violent and of difficult metering and control.

- The patent solution requested a mixed breathing technique with nose, to be used for the inhale phase, and mouth, to be used for the exhale phase. It is not reasonable indeed expecting the air exhale phase through the nose since no exhaust valves were provided inside the mask. This breathing process however is quite unnatural and probably more complex to be learned than the mouth-mouth breathing technique normally used in the Aqualung and in the other regulator models. Furthermore, we need to consider the disturbance caused by the air exhaust bubbles ahead of the mask’s glass. As we will see, this limitation on the breathing mode will remain also in the further versions of the mask and on the final configuration distributed on the market as well.

- We can suppose the use of this mask implied also problems with the ears compensation, problems which could not be solved using the classic nose clip (the nose had to be maintained fully cleared for the breathing inhale phase). Finally, there were also solid probabilities of mask’s glass fogging situations.

From the middle of the ’50 years, when Hawley started working on this project, to 1965, when Scubapro began the distribution of this product by his brand, the initial configuration of the mask had several modifications and improvement attempts. The most important ones are listed below:

-

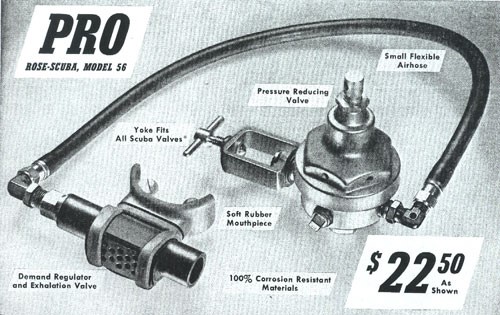

Addition of an air pressure reducing first stage between the mask and the tank valve. From the pictures included in the article mentioned above, it looks this first stage coupled with the mask was the same of the Rose-Pro model “56” regulator, the first “modern” single hose regulator manufactured in the USA by Rose Aviation Inc. starting from 1956 (see Fig. 21 and Fig. 22).

-

Relocation of the air supply demand valve from the lower area to the upper area of the mask, as in the McLean‘s patent. This solution, through a suitable orientation of the air supply valve, allowed the reduction of the mask’s glass fogging, thanks to the air flow partially lapping the internal surface of the glass. Concurrently to this modification, the initial tilt valve was replaced by a “downstream” type valve similar to those which would have become standard in the single hose regulators starting from the end of the ’50 years (i.e. the Scubair manufactured by Healthways or the Calypso manufactured by U.S. Divers)

-

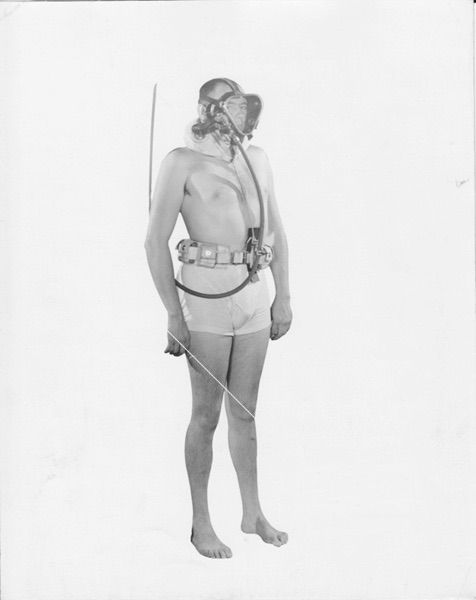

fig. 21 fig. 2 - Before the end of that decade, some performances tests were carried out by feeding in parallel the mask with other regulators which were available on the market in the USA in those times. In the article mentioned before one can see applications with the single hose regulator Aquamatic (see Fig. 23) and with the double hose regulator Aqualung DA Aquamaster (see Fig 24), both of them manufactured by U.S. Divers. However, in these cases, the mask worked as a spare air source, since the diver could breathe through his mouth by a normal regulator.

- After having checked these configurations, the next step was the evaluation a version with a full face mask configuration, namely with a full nose-mouth coverage, a configuration which looked to be more interesting for a professional applications market. Among the variants taken in considerations there was also one with a “bubble” shaped glass, namely with a polycarbonate spherical glass, a solution giving advantages in terms of visibility range but leading to several problems in terms of manufacturing processes and costs

-

fig. 23 fig.

- After the spherical glass solution was scrapped, the simpler and cheaper flat glass solution was adopted but confirming the full face mask configuration. A great care was given to the mask’s visibility which remained of great level thanks to the large surface of the front glass, designed with a fully circular shape.

- The last detail introduced in the final design of the “Visionaire” consisted in the air exhale duct located internally and crossing horizontally the mask. This duct, manufactured by injection moulding process as integral part of the mask’s rubber body, had a central housing where to lay the mouth for pulmonary air exhale. In the connection areas of this duct with the side walls of the mask’s body, two mushroom type check valves were installed (one for each side) and protected by small grid deflectors. These valves allowed the exit of the exhaled air but prevented the water ingress inside the mask (see Fig. 25 and Fig. 26).

-

fig. 25 fig. 2 Despite the requirement of the mixed breathing technique mentioned before (nose for the inhaling phase and mouth for the exhaling phase), this solution had the undoubted advantage to reduce the carbon dioxide accumulation inside the mask and to limit the possibility of the mask’s glass fogging caused by the warm and wet air coming off the lungs.

We are now at the middle of the ’60 years and about a decade had passed from when Hawley started to take care of this project. As you can see, the final result was something much different from the original idea and had transformed a mask, which should have been a simple and cheap piece of gear mainly for recreational and sports divers, in a quite professional product, surely more complex and expensive than the original targets.

However, Scubapro believed in the commercial possibilities of this mask and, in the initial phase, decided to distribute it through his sales network. In fact, the series production of the “Visionaire” has been already started in a handicraft way in 1964 when Hawley founded the family enterprise “Visioneering Unlimited” where, in addition to him, his sons worked as well. From his daughter Samara Hawley‘s tale, it looks like the rubber components of the mask were imported from Italy, probably due to the good relationships developed by Gustav Della Valle during his previous work experiences.

In 1966 however, Hawley sold to Scubapro the manufacturing rights and the production tools of the mask and, from that moment, the “Visionaire” officially became a Scubapro product (see Fig. 27) with his logo marked on the mask’s external metal frame (see Fig. 28).

fig. 27 fig. 28 The manufacturing of this mask ended in 1970 and, overall, the “Visionaire” never had that success his inventor before and Scubapro later hoped. And in fact in some countries, including Italy, the number of sold units was quite negligible (this fact, together the deterioration of the rubber components used to manufacture this mask, is the main reason of its rarity among the national collectors).

Let’s now analyze the reasons of this commercial flop.

One of these causes was undoubtedly its price which was significantly higher than that of a normal mask plus a separate regulator, a reason shared also by Samara Hawley in her article.

Prendendo infatti come esempio il catalogo Scubapro del 1968, il prezzo di listino di una “Visionaire” equipaggiata con un primo stadio MKII era di 95 $ mentre il prezzo totale di una maschera base Scubapro (abbiamo preso come esempio il modello Marin che costava 5,25 $) con un erogatore MKII/R108 (che costava a listino 55 $) era di 60,25 $ e cioè più di un terzo in meno, differenza che il subacqueo medio non era disposto a pagare, anche perché non trovava quei vantaggi che avrebbero potuto giustificare tale differenza di prezzo.

La “Visionaire” poteva essere competitiva dal punto di vista economico nei confronti di maschere granfacciali di tipo professionale ma, rispetto a queste, aveva alcuni problemi residui, che naturalmente non troviamo descritti nell’articolo della figlia di Hawley, e cioè: - The typical breathing cycle necessary in the use of this mask (inhale through the nose and exhale through the mouth) made it impossible the applications of any solution making the compensation easy, like nose clips. Therefore, the compensation remained one of the main problem to solve in using this mask, a problem not easy to face by an average sports diver. Moreover, this breathing cycle remained very limiting when compared with that offered by other full face masks which could be used indifferently with nose and/or mouth breathing cycles.

- The use of the mask’s glass as pressure balancing diaphragm, although looked a brilliant idea, led to some technical limitations which were never eliminated neither through the several solutions and the many variants proposed during its long development phase. The main problem was the weight of the glass and the elasticity of the mask’s body designed to allow the glass rotation and the air supply demand valve actuation. This weight, much higher than that of a normal second stage diaphragm, had a negative dynamic effect in terms of very slow reaction times during the initial and the final air supply phases. This effect could never been eliminated. Namely, the initial and the final air supply phases were much delayed when compared to the typical performances of a common second stage, with a consequent breathing hardness felt by the diver. In addition, the elasticity of the mask’s rubber body could not have been reduced too much to prevent free flow conditions due to simple water movements perpendicular to the mask’s glass surface, movements caused by the diver’s swimming or by medium/strong currents. Despite several attempts in optimizing these parameters, this mask remained much more sensitive to the free flow conditions than the other models of the competitors having a fixed glass.

After the experience of the “Visionaire” the other full face masks manufacturers definitively gave up with the glass/pressure balancing diaphragm idea, which was apparently a brilliant and fascinating solution in terms of technical principles, but completely weak-willed and disappointing in terms of practical application and performances. They focused on other fundamental aspects of these masks like the elimination or the reduction of the carbon dioxide accumulation, the easy pressure compensation and the anti-fog capabilities.

However, also with the improvements introduced during the following years and despite the promotional campaign on these products and the training agencies initiatives (see the full face masks training courses dedicated to the sports divers starting from the ’90 years), this type of mask was never able to definitively penetrate the recreational diving market. It still remains associated with professional, military and scientific applications.