As long as the Frenchmen Cousteau and Gagnan are widely recognized to be the inventors of the modern SCUBA unit, in its double hose version, conversely in the historians and collectors community there is no unanimous consensus on who invented the single hose SCUBA unit. This unit, throughout continuous modifications and improvements, would have become the breathing apparatus most widespread and used by the modern divers, still nowadays.

The design and development phases of the Cousteau-Gagnan regulator are well known and widely described in the several books and underwater movies of the captain Cousteau himself. In order to see the first development attempts of alternative double hose regulators, one would have wait at least ten years.

As far as the single hose regulator is concerned, in reality there was the development of devices also very different each other, with solutions more or less original, practically at the same time and in several countries around the world. What happened frequently was that the inventor of a certain regulator was still unaware of what his direct competitors were doing. Moreover, keep in mind that, after the WWII and during the ’50 years, the communications among the several geographic areas of the world were scarce and difficult. Therefore it is absolutely understandable these persons had no idea about what was designed and developed elsewhere, as we will see soon.

The reasons for what it is difficult to establish the true inventor of the single hose regulator are several. The main ones are listed below:

- The breathing apparatus were frequently derived from military breathing devices, easily obtainable as surplus material after the end of the WWII. Therefore, many components of the regulator were directly taken from these military breathing systems.

- The modifications described above were carried out in a crafts way and were frequently developed many versions of the apparatus before it showed satisfactorily performances.

- Of these numerous crafts versions no drawings, schematics and other documentation, capable to provide solid and consistent information necessary to the researchers and the historians to clearly identify and date these models, was ever produced.

- In some cases, also for very important models, no patent request was ever presented.

- The production of these devices during their early development phase, except for some particular cases, remained limited to tens or hundreds of units at the maximum. The market at that time, still not completely developed, was strongly dominated by the production of the double hose Cousteau-Gagnan type regulator with companies commercially very strong like La Spirotechnique in Europe and its controlled firm U.S. Divers in the USA. These companies strongly opposed and sometime prevented the distribution of competitive products.

- Until the beginning of the ’60 years the performances of these single hose devices were almost never aligned with those of the double hose regulators. In some cases, the distribution of single hose models turned out to be a real “flop” with the needs sometime to withdraw the regulators from the market soon after the beginning of their sales phase. Therefore, their spread in the market remained very limited and sometime restricted at few prototypal versions. Except for particular cases, the main reason pushing the designers to work on this configuration of regulator was to propose a solution on the market which, although having acceptable performances but not necessarily comparable with those of the double hose models, was much cheaper and then much more desirable for the users at that time.

- Some single hose regulators developed in those years had a single pressure reducing stage including also a demand type air delivering device. Consequently, the regulator’s tube was a corrugated tube having the same dimensions and characteristics of those installed on the double hose models. In some cases, the corrugated tube was connected to a full face mask provided with an air exhaust valve.

-

These configurations, sharply different from the single hose regulator features, which would have become the standard ones in the following years (first pressure reducing stage to an intermediate value, second stage with a demand type air delivering device provided with a mouthpiece and an exhaust valve and a small section hose connecting the two stages) sometime were not considered by the researchers as representative of the development of this regulator.

Although with all the identification difficulties explained above, however a short chronicle of the main events, devices and characters somehow linked to the development of this regulator. The readers will take the final decision, based on their experience and feeling, on who can be indicated as the true inventor of the single hose regulator.

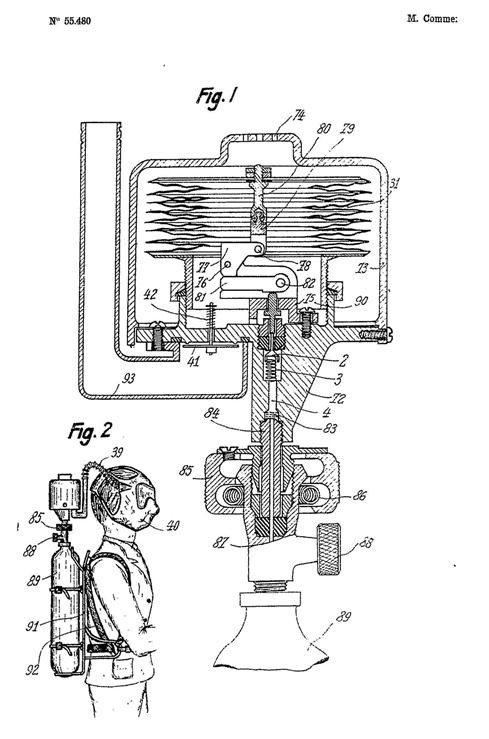

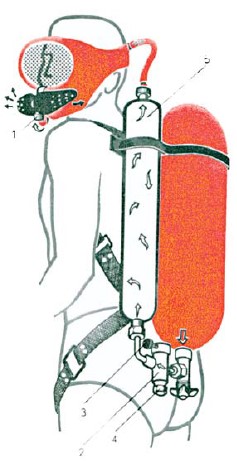

1942 – The French George Commeinhes starts producing the diving apparatus called “G.C.-42 Amphibie” (see Fig. 1 and Fig. 2). This device was developed starting from a breathing apparatus used for mines rescue and for the protection of the firefighting teams and patented by his father René in 1935. The production configuration was made of two compressed air tanks, installed inside a dedicated aluminum shaped box, a harness, a tank valve, a diaphragm type pressure reducing device, a corrugated hose and a rubber full face mask provided with a pre-set air exhaust valve.

Commeinhes himself, during a demo dive, reached a depth of 53 meters with this device. The G.C.-42 device was adopted by the French Navy as well.

Unfortunately the inventor, who was part of a tank crew, was killed during the battle for the liberation of Strasbourg (1944)

The family company continued the production of this device for some years and on the market an improved model as well, the G.C.-47.

|

|

| fig. 1 |

fig. 2 |

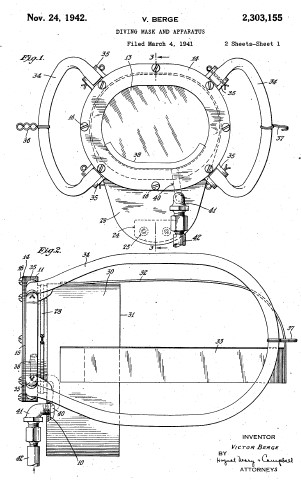

In the same year the Swedish Victor Berge obtained the U. S. patent U.S. 2.303.155 for a “Diving Mask and Apparatus” (see Fig. 3 and Fig. 4).

|

|

| fig. 3 | fig. 4 |

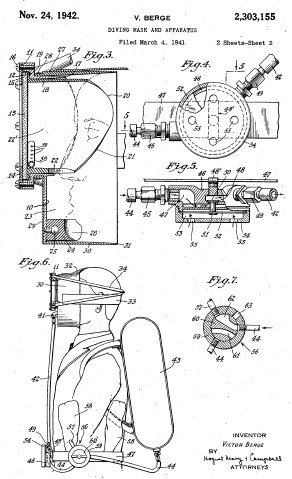

1943 – The Ohio Rubber Company starts the production for the U.S. Navy of a shallow water breathing system based on the Victor Berge patent (see Fig. 5 and Fig. 6).

|

|

|

| fig. 5 | fig. 6 |

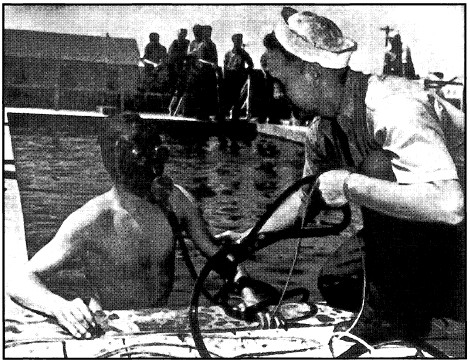

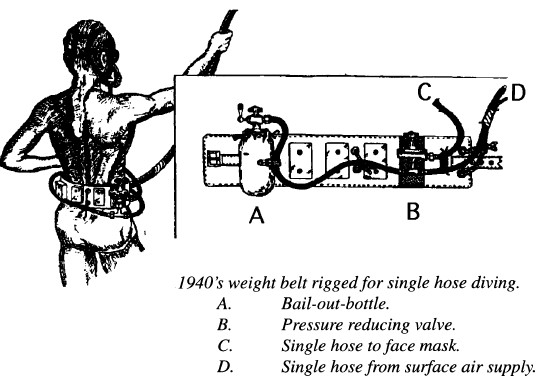

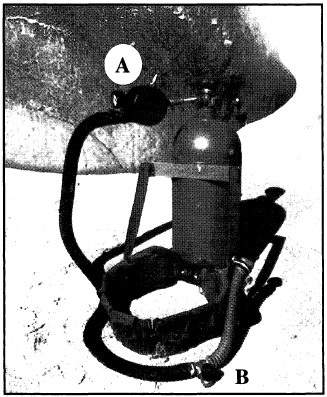

This system, modified with respect to the scheme of the patent above, was supplied from the surface through a low pressure pump (hookah). This breathing system, widely used during the second world war (see Fig. 7), will be handcrafted modified, immediately after the end of the war, by some North American divers to become a true SCUBA unit without any air feeding from the surface. Among these divers, there was also Ector Royal Cross, one of the American diving pioneer, who implemented some modifications to the U.S. Navy system in order to improve its performances. These modifications, shown in Fig.8, consisted in the addition of a pressure reducing device and of a bail-out tank to the weight belt. In such a way the surface compressor pressure level could be increased and an emergency air feeding system could be provided.

|

|

| fig. 7 | fig. 8 |

1947 – In number 10 of the Historical Diver magazine, issued by HDS USA, E.R. Cross himself tells to have faced a true SCUBA unit with a single hose regulator at the beginning of 1947 at San Pedro beach, California. This device was derived from an oxygen breathing system, taken from a military aircraft of the Second World War and properly modified (see Fig. 9). This regulator, used for spearfishing, was made by a single stage, with double function of pressure reducing device and of demand type inhaling valve, installed on an air filled tank. A long corrugated hose linked this pressure reducing device to a mouthpiece provided with a check valve. A second corrugated hose with a duckbill valve discharged the exhaust air to the external environment. Cross convinced the inventor-owner of this regulator (whose name remained unknown) to sell him the handcrafted SCUBA unit for 50 dollars. As Cross remembers in this article, it is likely hundreds of similar units have been handcrafted modified, starting from military aircraft oxygen breathing systems which were available at that time, in great quantities and at very cheap prices, as military surplus material. These units were used mainly for spearfishing. Also one of the double hose regulators manufactured at that time in the USA, the rare Sea Horse produced by Dive-Craft Industries from Pittsburgh PA (see Fig. 10), was developed starting from oxygen dilution/breathing systems taken from military aircrafts.

|

|

| fig. 9 | fig. 10 |

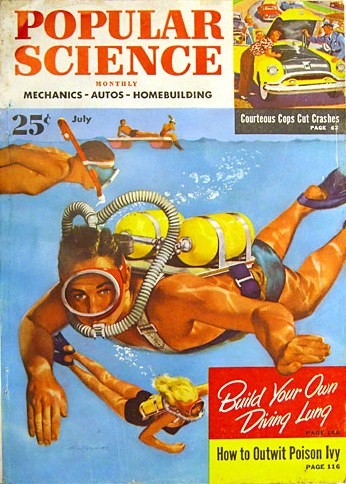

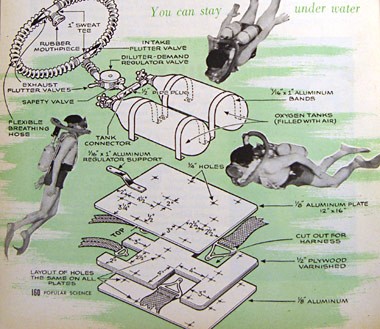

After all in the USA, during the early ’50 years, the handcrafted building of the underwater regulators, not only was tolerated but rather generally encouraged. Even in the July 1953 issue of the “Popular Science” magazine, the famous article “Build Your Own Diving Lung” was published. In this article, the whole process of obtaining a diving regulator starting from an aircraft oxygen breathing device, easily obtainable as surplus material in the military warehouses (see Fig. 11 and Fig. 12).

|

|

| fig. 11 | fig. 12 |

By the end of 1947 Cross modified the regulator purchased at 50 dollars by moving the pressure reducing device on the weight belt and replacing the mouthpiece by a full face mask (see Fig. 13).

|

|

| fig. 13 | fig. 14 |

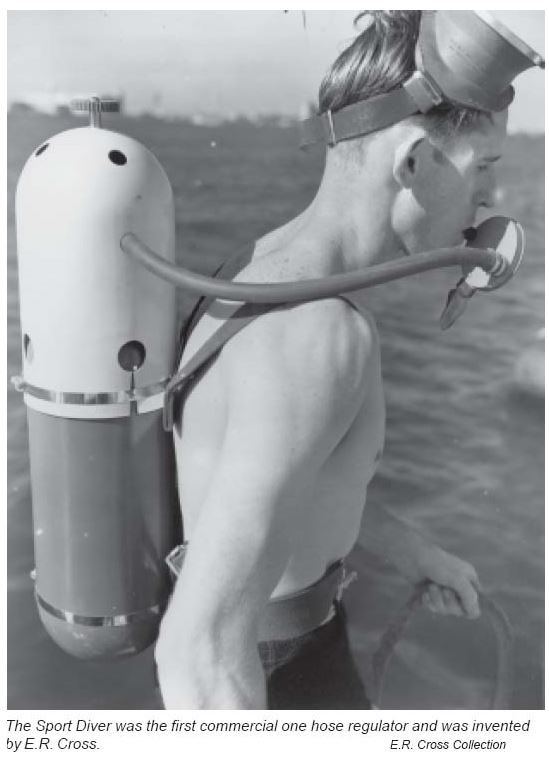

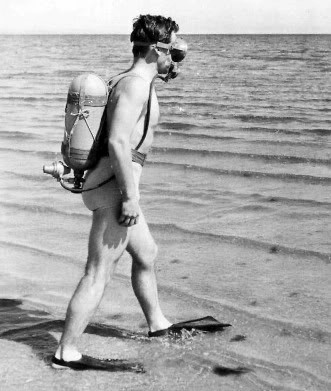

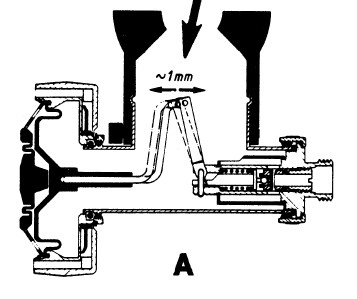

1949 – Cross continued to check several modifications and solutions until a final configuration of this regulator was defined. This configuration was then put in the market, from this year to 1953, with the name of “Sport Diver”. The pressure reducing stages became two: a first pressure reducing stage, very simple and sturdy, installed on the tank and a second stage provided with a mouthpiece, with a duckbill exhaust valve and with a demand type “downstream” valve (see Fig. 14).

The intermediate pressure between the first and the second stage would have been significantly lower than that of the regulators used nowadays (less than one bar versus 9/10 bar of the modern regulators). Therefore, the connection hose would have been remained the same used on the double hose regulators with large section and corrugated external surface (see Fig. 15). This configuration was practically identical to that would have had success in the following years. In its final version, the intermediate pressure was slightly increased so allowing the replacement of the large section corrugated hose with a smaller section not corrugated hose, similar to that used in the modern regulator (see Fig. 16).

|

|

| fig. 15 | fig. 16 |

The main design target for E. R. Cross was to build a very simple and reliable breathing device but, above all, a regulator much cheaper than the model dominating the market in those years: the Aqualung by the U.S. Divers. As you can see in Fig. 15, a complete Sport Diver SCUBA unit could be purchased for approximately 80 dollars meanwhile a complete Aqualung having the same configuration costed 150 dollars (see the 1953 U.S. Divers catalogue). About 1000 Sport Diver regulators were sold overall until 1953 when Cross decided to end the production of this model for the difficulties in procuring the scuba tanks (at that time no industries existed in the USA capable to manufacture them and therefore those had to be gathered from other applications) and for other duties overtaken in that period. As consequence, this regulator remained unknown in Europe for many years.

1950 – Unaware of the developments occurring in the USA at a handcraft level on this device, the Australian Ted Eldred independently designed a single hose two stages regulator, based on severe technical specifications received from the Australian Navy. This device was registered with the name “Porpoise”. The main target of this design was to develop a regulator not only compatible with the original Cousteau-Gagnan patent with no risk of infringement but, above all, having better performances. Considering that the potential customer of Eldred for years remained the Australian Navy, among its main targets this design had not the reduction of its production costs. In fact, this regulator was widely recognized to be technically well designed and of high quality manufacturing standards as well as with performances much better than those of the double hose models, manufactured at that time by La Spirotechnique. Oddly, both Cross and Eldred never patented their devices. Both of them justified this choice with lack of funds, with the poor interest the market at that time seemed to attribute to their inventions and with their concerns about potential legal conflicts with powerful companies like the U.S. Divers in the USA and La Spirotechnique worldwide.

1952 – Ted Eldred founded the Breathing Appliance Company located in Melbourne and started the production and the sale of the Porpoise, mainly to the Australian Navy (see Fig. 17 and Fig. 18).

|

|

| fig. 17 | fig. 18 |

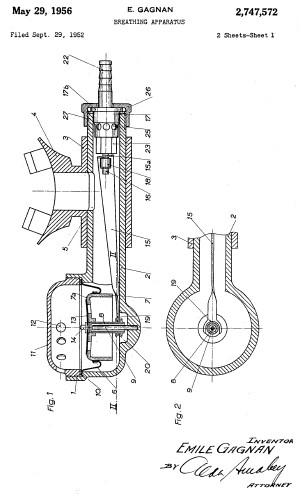

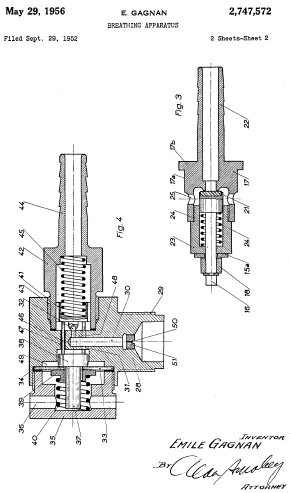

At the same time, Emile Gagnan, from his laboratory-office in Canada, at Montreal, reacted immediately to the commercial attack on the North America market consisting of the extremely cheap Sport Diver and presented the patent n° 2.747.572 (see Fig. 19 and Fig. 20). Based on this patent, the first single hose model manufactured by the U. S. Divers, the Aqua-Matic would have been developed (see Fig. 21). However, this model did not entered into its production phase before 1957 and with a second stage actuation valve mechanism, completely different from that shown in the patent itself (see Fig. 22).

|

|

| fig. 19 |

fig. 20

|

|

|

| fig 21 | fig. 22 |

Unfortunately the performances and the reliability of this regulator were very poor and therefore the U.S. Divers had to stop its production after few years.

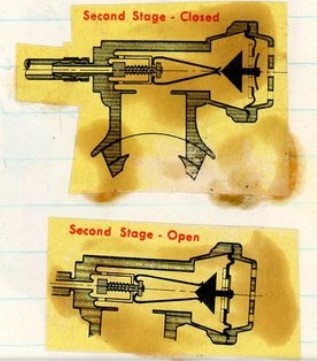

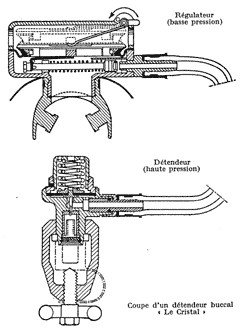

Practically, at the same time and without any knowledge of the developments in the USA and in Australia, as explained above, Jean Armand Luis Bronnec and Raymond Maurice Gautier from Marseille, after having founded the Cristal company, started to produce the single hose regulator “Explor” (see Fig. 23 and Fig. 24).

|

|

| fig. 23 | fig. 24 |

Although put in production at the end of 1952, the request of patent for this model was presented not before 1955 and the French patent was released in 1956.

This distribution attempt, even on its own territory of a competitive product, was considered unacceptable by the powerful French group Air Liquide, the owner of La Spirotechnique. This latter felt to be the absolute dominator of the market. A lawsuit followed for presumed violation of one of the Cousteau-Gagnan patents. This lawsuit oddly led to the victory of the two inventors from Marseille. Not being able to win the lawsuit against the Cristal Explor threat, La Spirotechnique convinced Bronnec and Gautier to sell them the patent. The production of this model definitively ended in 1964.

1954 – In Germany some developments in this area are observed as well. In this case, the most active company was the Draeger from Lubeck, which put in the market the strange regulator called “Dolphin II” (see Fig. 25 and Fig. 26), more as a cheaper reply against the CG-45 Cousteau-Gagnan regulator than a true contribution to the development of the single hose regulator. Not by chance, this model is mostly included, by the collectors, among the double hose regulators. It was a single stage regulator with just one corrugated hose provided with a mouthpiece, at one of its end, and with an air exhaust valve installed in the regulator’s main body. Perhaps unique case in its kind, it was a regulator with a “pendular” air flow. That means that both the inhaled and exhaled air flows passed through the same hose but in opposite directions, exactly as in the oxygen rebreather models of Italian production.

|

|

| fig. 25 | fig. 26 |

In the same period in the USA other manufacturers came forward with new ideas and solutions, not necessarily to compete with the Sport Diver, a regulator which had earned poor visibility and importance in the market, mainly due to its very limited production volumes, but primarily to get market-share from the Aqualung.

One of the most important attempt along this direction was that carried out by the «Scott Aviation», a company from Ohio founded by the Canadian Earl Scott, who proposed, starting from 1954, the single hose regulator named «Hydro-Pack». This device consisted of a tank with its valve mounted downward and its related harness, of a first stage with intermediate pressure adjustment external knob and of a full face mask provided with a pressure reducing second stage equipped with a demand valve and of an air exhaust valve (see Fig. 27 and Fig. 28). It was a very appreciated regulator model for the quality of its materials (of aircraft industry level) and for its performances. Unfortunately, this model had a very limited spread in the market since of its high purchasing cost. In addition the ear compensation problem underwater remained. It could be solved by using simple nose clips.

1955 – Although in Italy the local manufacturers started with some delays in developing this device, at middle of ’50 years some attempts materialized, surely very original from a technical standpoint but unfortunately having a poor success from the sales and production volumes perspectives. A remarkable device was surely the “Tricheco” (Walrus) regulator manufactured by Pirelli (see Fig. 29 and Fig. 30). It was a single hose regulator with a cylindrical shaped first stage, installed on the tank’s side, a full face mask, including the air exhaling device, a foldable snorkel, to be used during surface swimming and an air exhaust system shaped like “Tricheco (walrus) tusks” from which the typical name.

|

|

| fig. 27 | fig. 28 |

The extreme rarity of this regulator among the collectors and the museums, witnesses the very low units really manufactured. It was indeed the first single hose regulator to be designed and manufactured in Italy.

|

|

| fig. 29 | fig. 30 |

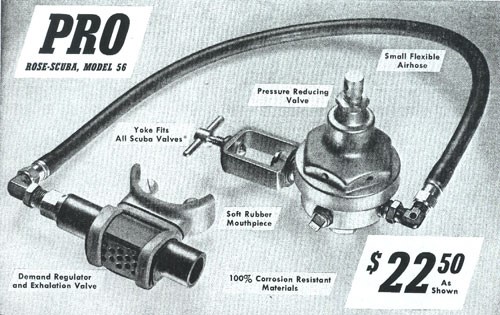

1956 – In the USA, after the experience of the Sport Diver of E.R. Cross, more manufacturers decided to develop similar solutions, maybe with higher quality and performance levels. One of them was the Rose Aviation Inc. from Aurora, Ohio which founded the division Rose-Scuba and manufactured the single hose model called “Model 56 Pro” (see Fig. 31). From now on the technical configuration settled in the following elements: pressure reducing first stage installed on the tank’s valve and second stage provided with inhaling valve, mouthpiece and air exhaust valve. This regulator had several updates along the years. The first model remained in its production phase in 1956 only; the second model, identified as «Pro Custom» was produced from 1957 to 1960 (see Fig. 32); The third and last model, sold as «Pro Super», was manufactured in 1961 and in 1962. The first stage, not balanced, was of diaphragm type and included a pressure relief valve necessary to safely work with a second stage tilt type «upstream» inhaling valve. The second stage main body was made in plastic material and included a front diaphragm activating the tilt type inhaling valve and an exhaust side diaphragm for the exhaled air. The same manufacturing principles were reused by Nemrod some years later with the model «Snark II».

|

|

| fig. 31 | fig. 32 |

1958 – In the cold Sweden as well, the new developing market was noticed and, among the early diving industrial realities there was the Poseidon, a company founded by Ingvar Elvström in 1958. In the same year of the production activities start the “Cyclon” regulator was presented (see Fig. 33 and Fig. 34), a model having a significant commercial success, especially in the professional diving applications, being recognized as a high performances and great reliability product.

Incredibly this model, after continuous improvements along the years, is still in production. Specific features of the second stage design are the mechanical linkage between the diaphragm and the valve and the composite diaphragm working as exhaust valve as well. The balanced diaphragm type first stage also contributed to the success of this regulator. This first stage was used on other models manufactured by Poseidon as well (i.e. Jet Stream Odin).

We conclude this list of single hose regulators, put in the market before the end of the ’50 years, again with a completely Italian model: the famous Pirelli “Explorer” invented and patented by the doctor, who was also red coral collector and dive recordman, Alberto Novelli and by Pietro Buggiani, a Neaples Italsider‘s technician.

|

|

| fig. 33 | fig. 34 |

This regulator, whose patent request dates to the end of 1958, would have been manufactured in three versions: the “Standard” (see Fig. 35), the “Maior” (which would have been remained at its pre-production condition and the “Minor” (see Fig. 36). Off course these devices included a exhaust air recovery system as well but, from a manufacturing standpoint, they were true single hose regulators. Just for the shortages in information coming from the other areas of the world, in those years many Italian divers thought the Explorer was really the first single hose regulator ever produced in the world.

|

|

| fig. 35 | fig. 36 |

1960 – La Spirotechnique purchased from Ted Eldred the Breathing Appliance Company so acquiring also all the customers the Porpoise earned along the years (mainly the Australian Navy).

Finally, we are arrived at the ’60 years and, from now on, the single hose regulators quit their germinal development phase, distinguished by several variants and technical solutions, but also by poor results in terms of performances and sales volumes, and entered in their full maturity phase so representing serious competitors of the double hose regulators. Their performances became still better than the double hose regulators and their manufacturing costs significantly cheaper. Therefore, starting from the early ’60 years on, these latter gradually but inexorably started to lose ground against the former until their complete production phase-out (except some particular cases) by the middle of the ’70 years.

____________________